3D Wolsung Terrain (spring cleaning challenge 2023)

Recommendations: 452

About the Project

Back around 2017, after watching BOW-OTT demoing Wolsung steampunk skirmish game i was hooked. I back their first Kick starter and started playing some game with what hero and henchmen i could get on Ebay. I always love the Wolsung terrain but it was hard to find here in the US. 2017 I also got my first 3D printer and try to create some terrain to match the MDF terrain from Micro arts studio was a disaster for the start. The PLA filament i used cause a lot of issue with the 3D model i made in tinker CAD. Clogging and under extrusion made my first prints weak and unusable. My plans to make the interior of an Airship were dashed :(. Fast forward to today i have desided give this project another go and see what i can do.

Related Game: Wolsung SSG

Related Genre: Steampunk

Related Contest: Spring Clean Hobby Challenge 2023

This Project is Active

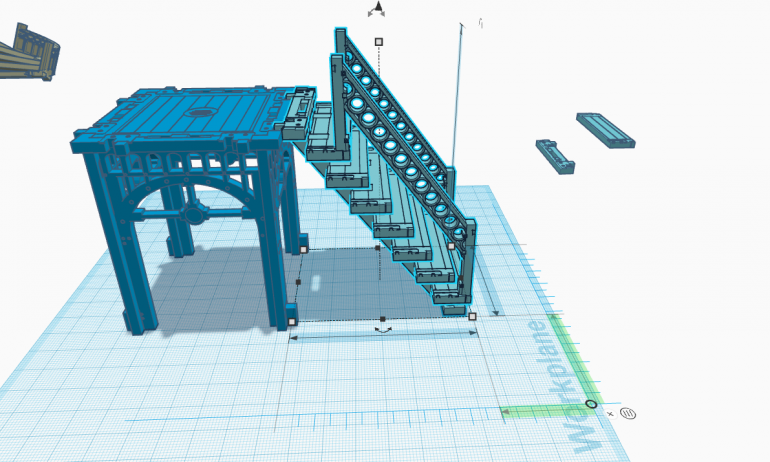

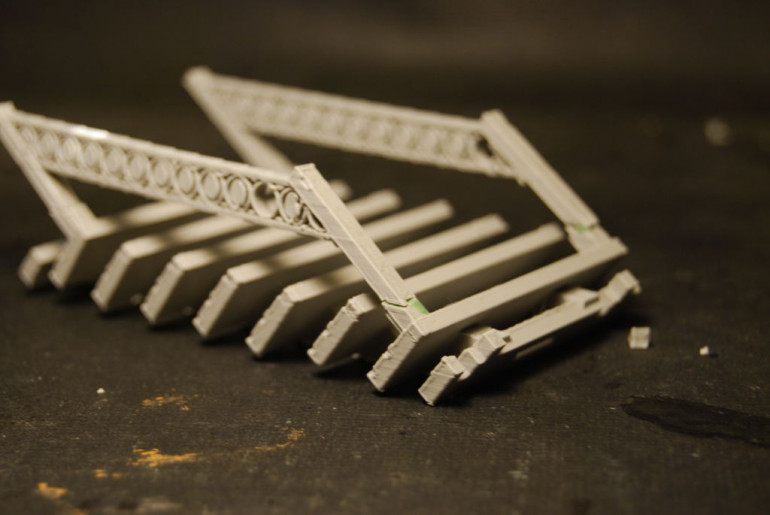

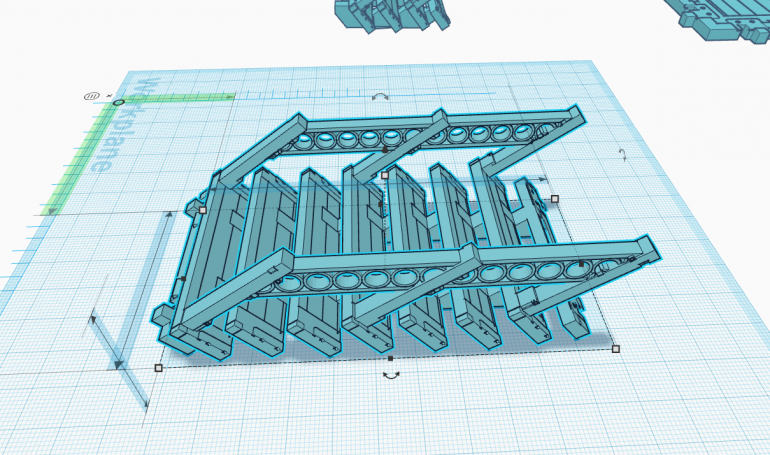

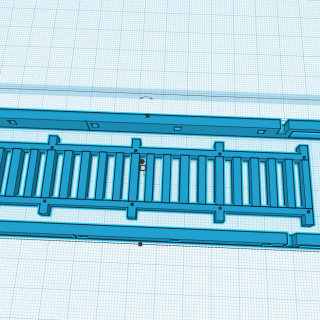

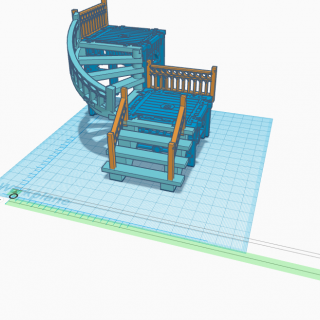

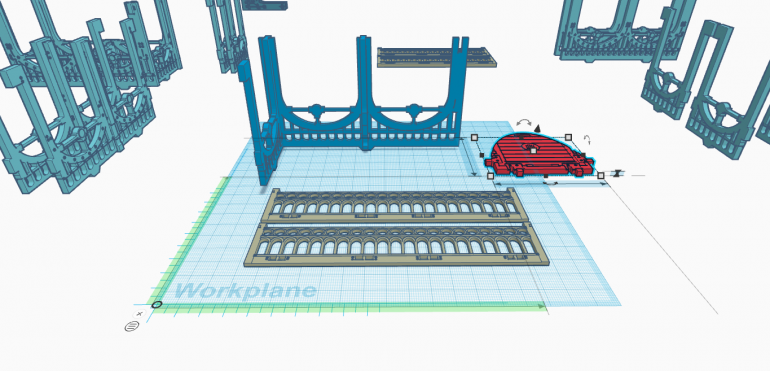

Stairs

Started working on some stairs design base on the Mirco Arts studio MDF version. It didnt fit what i wanted.

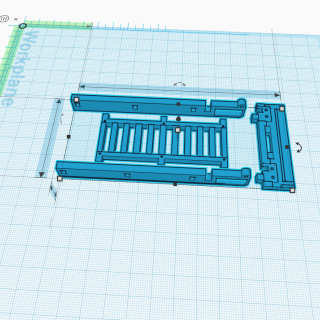

Ladders

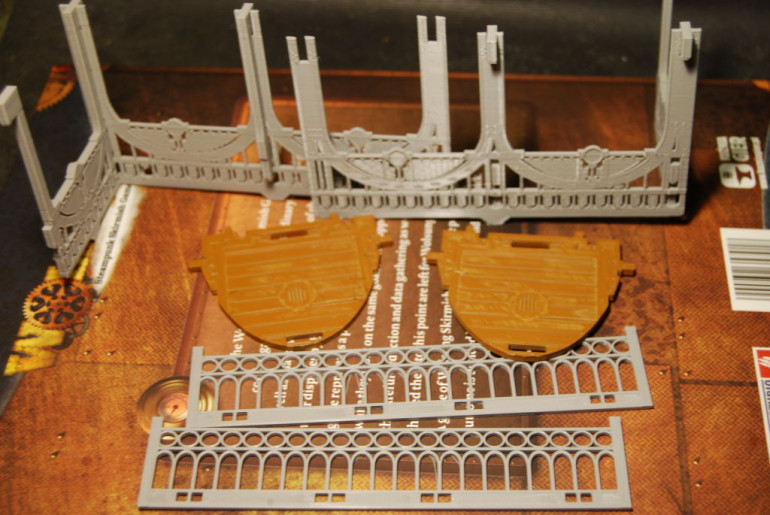

I made some ladders design base on the MDF ladder found in Wolsung.

Hot off the printer with some tight tolerance. i had to trim to fill each tab on both ladders, at least i didnt need to glue them together.

Hot off the printer with some tight tolerance. i had to trim to fill each tab on both ladders, at least i didnt need to glue them together.grand stairs case complete

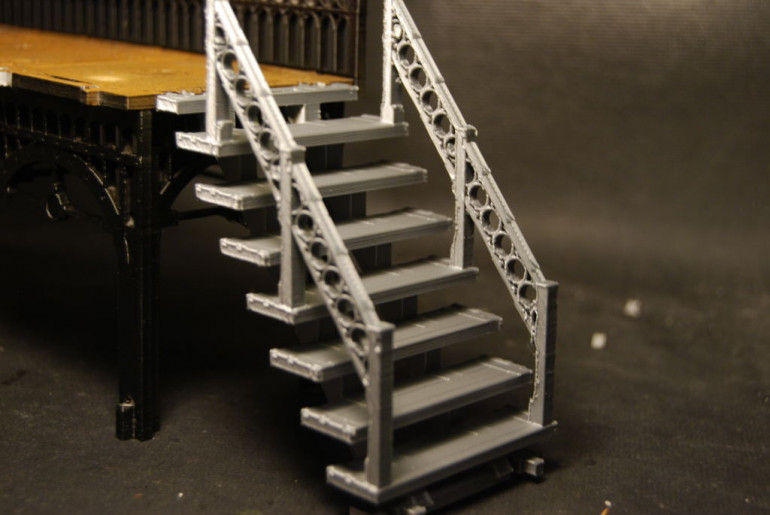

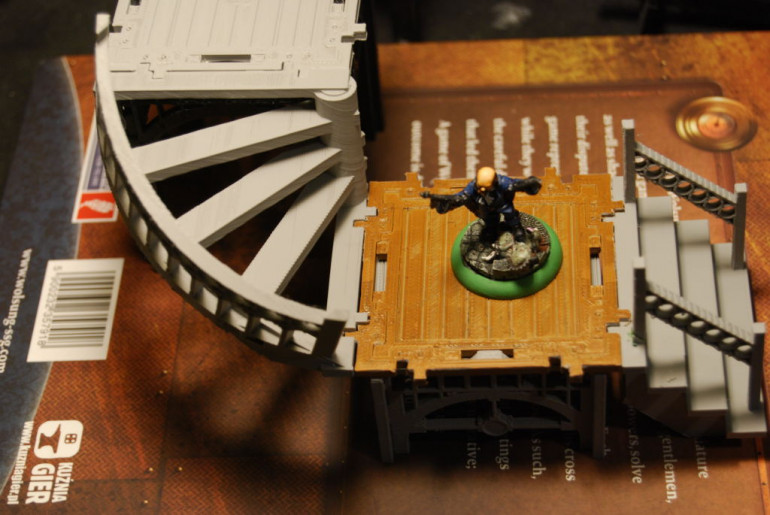

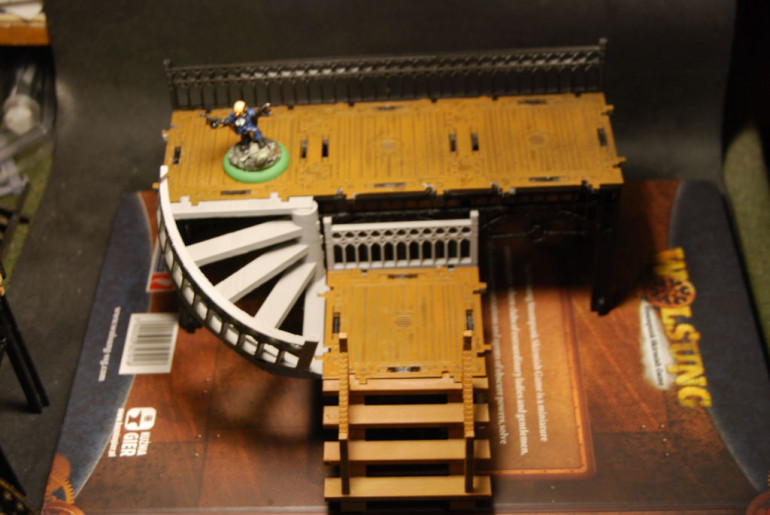

Grand stair case

I have tried to make a grand stair case out of MDF ,but it wasnt quite grand enough:).

Overall i am happy with the look. I just had a issue with alignment of the short stair not matching up.

Overall i am happy with the look. I just had a issue with alignment of the short stair not matching up. Triple Arch

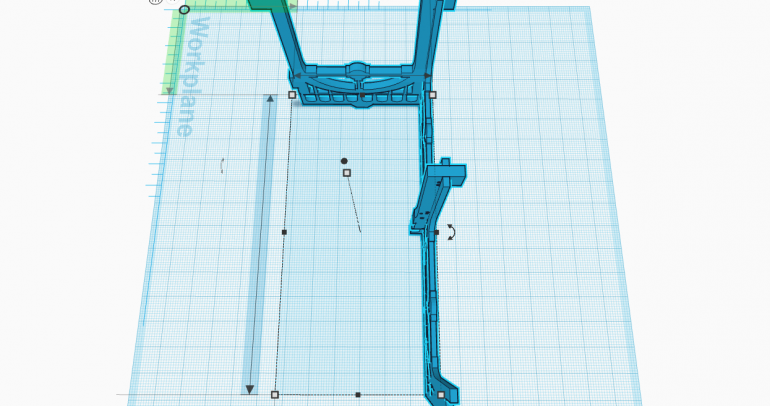

Micro arts studio didnt make anything that would traverse over streets. so i mashed together some walkway file.

Waiting for my next print to finish

By the way, I running a Creality CR-10s with a build volume of 300mm by 300mm x 400mm it my second FDM printer after my first one had a motherboard failed.

The filament i mainly use is Hatchbox PLA (Grey) or Esun PLA+. i have tried cheaper brand like sunlu and sayo, got varies results. i found the cheaper bands damage my nozzle faster so the 0.4 nozzle wear out in about 2 KG (spool) to 3 KG worth of filament.

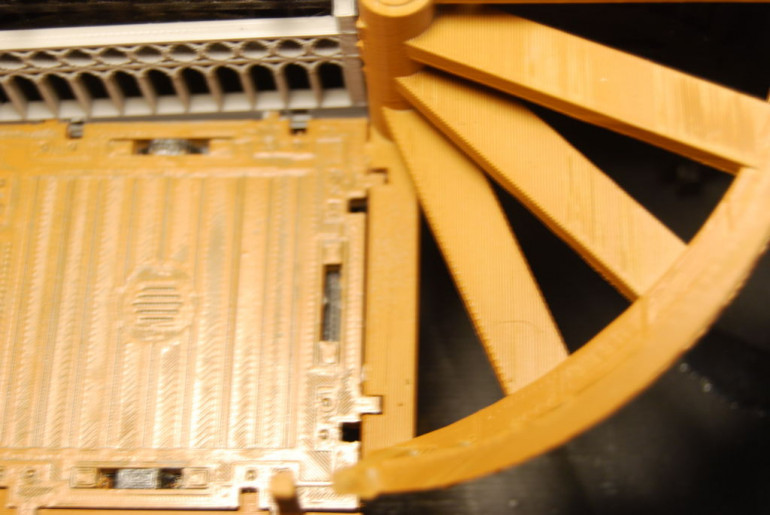

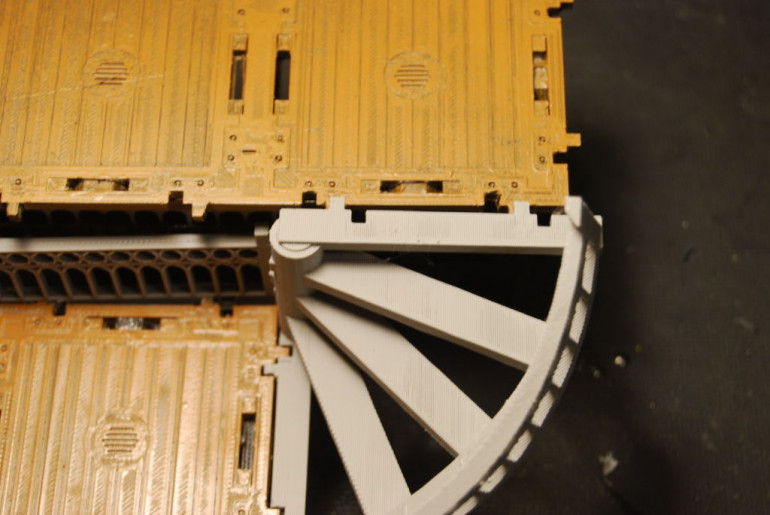

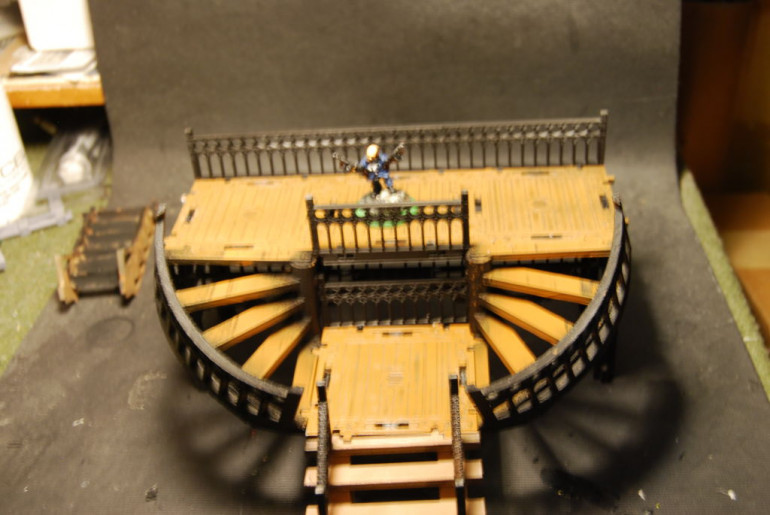

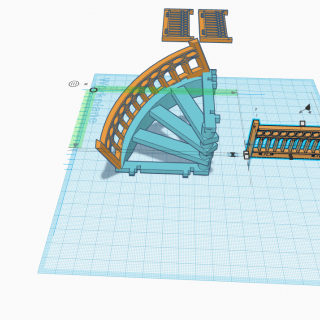

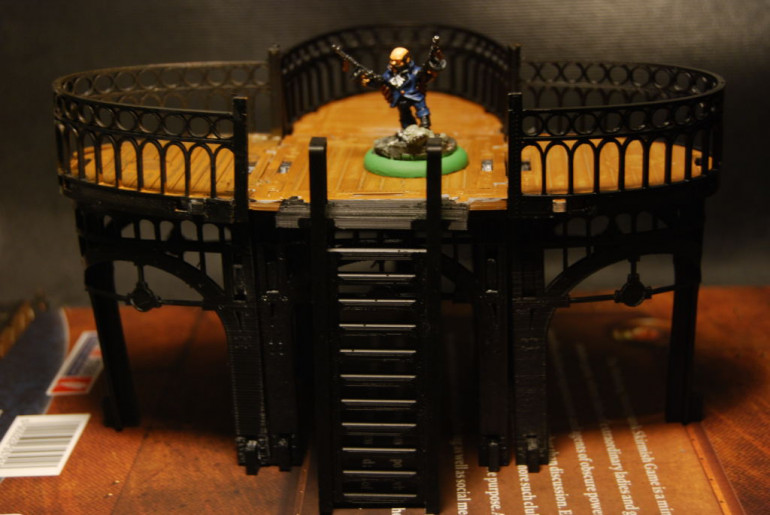

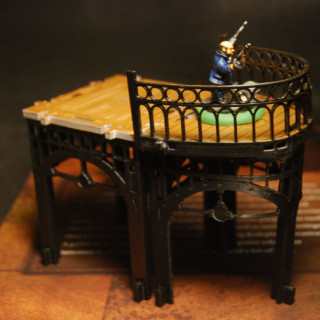

Curved balcony

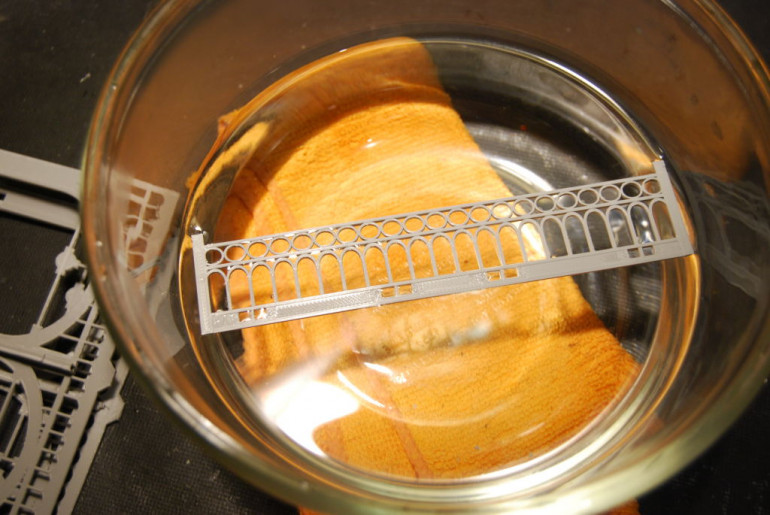

One thing MDF kit struggle with are curves parts. That were 3D print can excel.

My secret is hot water(not scalding) dip part for a sec to test the filament reaction. It should take a few second to become malleable. Use cold water to set the shape just like resin.

My secret is hot water(not scalding) dip part for a sec to test the filament reaction. It should take a few second to become malleable. Use cold water to set the shape just like resin.It look pretty cool. I am very happy about the way these turn out :).

Double arch disaster

Last week i spent some sleepless night correcting the test printing terrain files. I should have just went to bed. Lesson learned lol :).

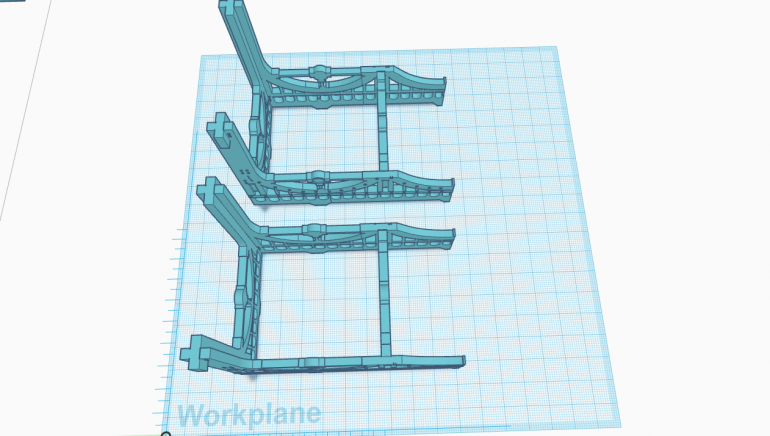

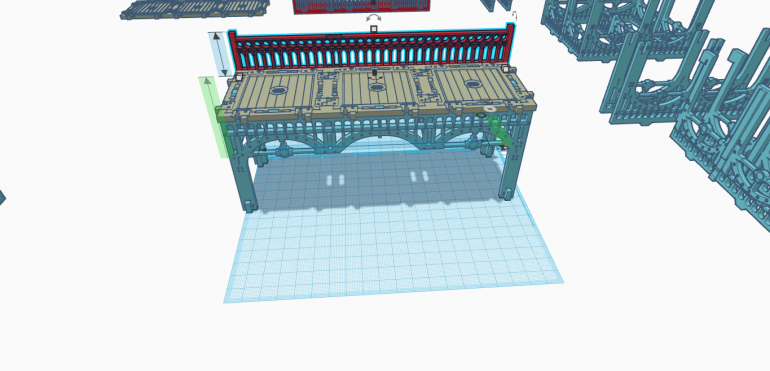

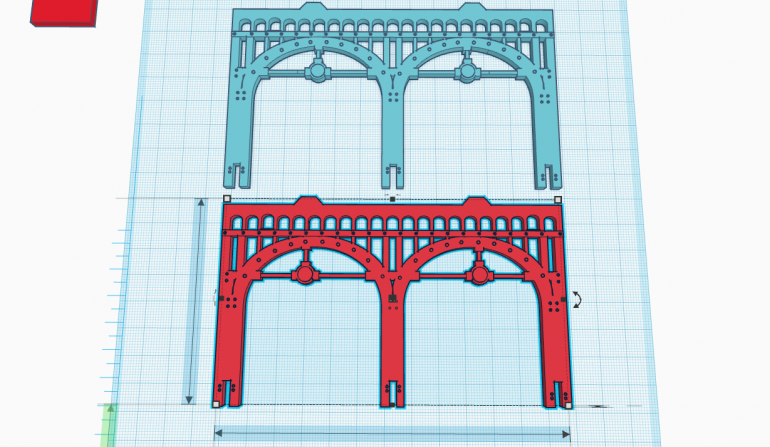

Concept for a 2×2 walkway that i didnt need and spent way to many hours tweeking the design and print failure and mistakes.

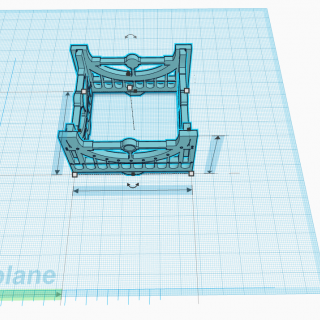

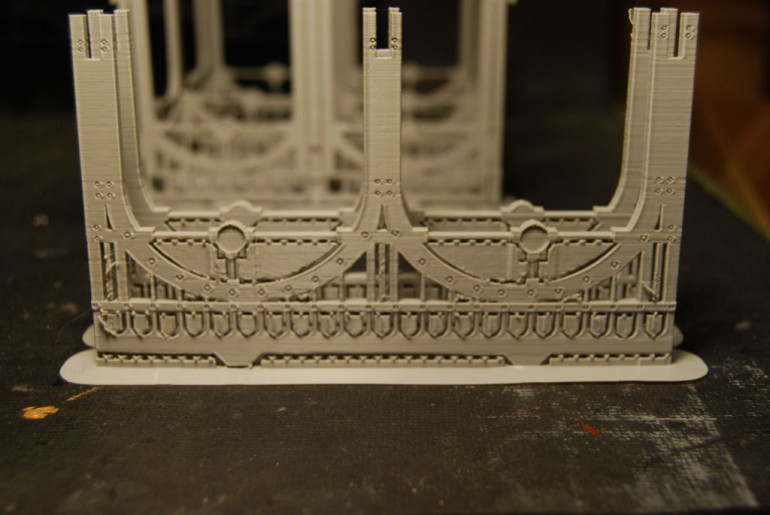

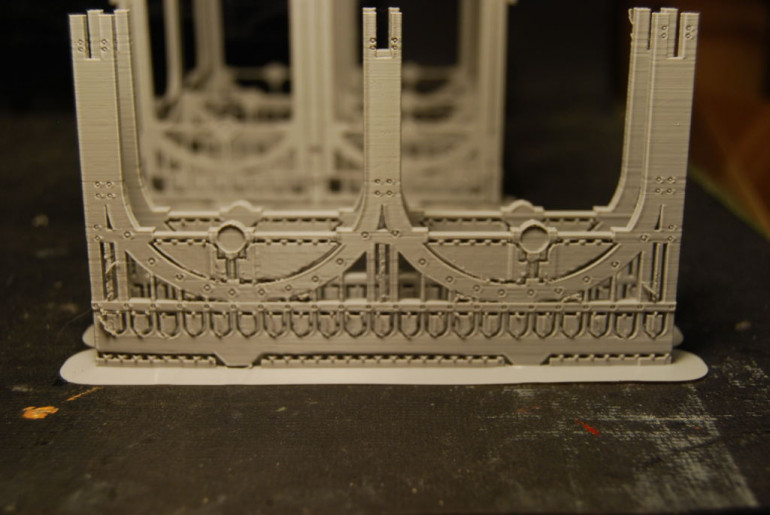

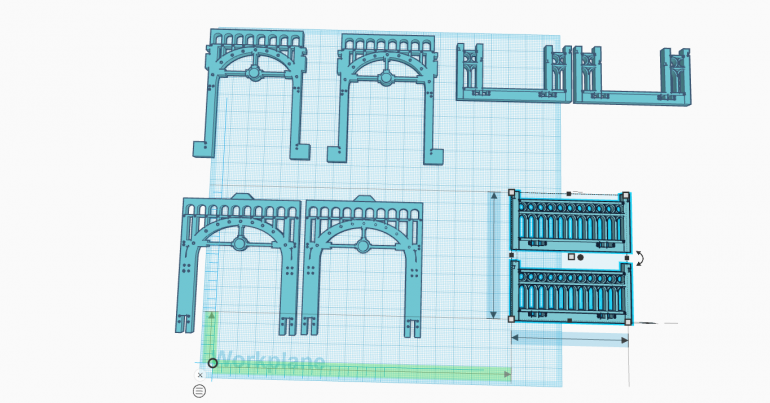

Resurrecting an old idea.

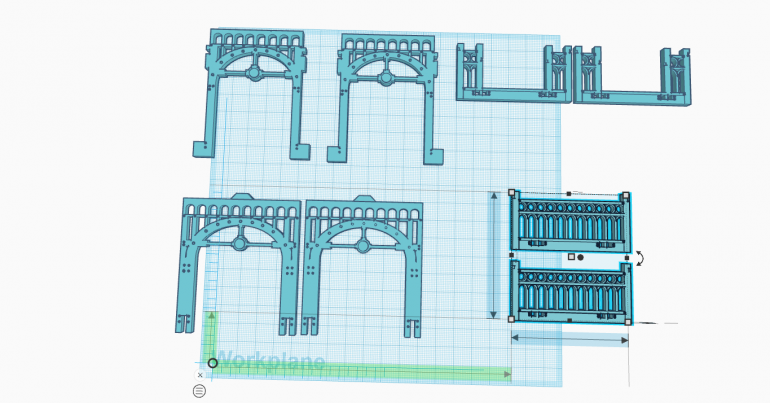

Looking through my files i made in 2018 for Wolsung it look promising .

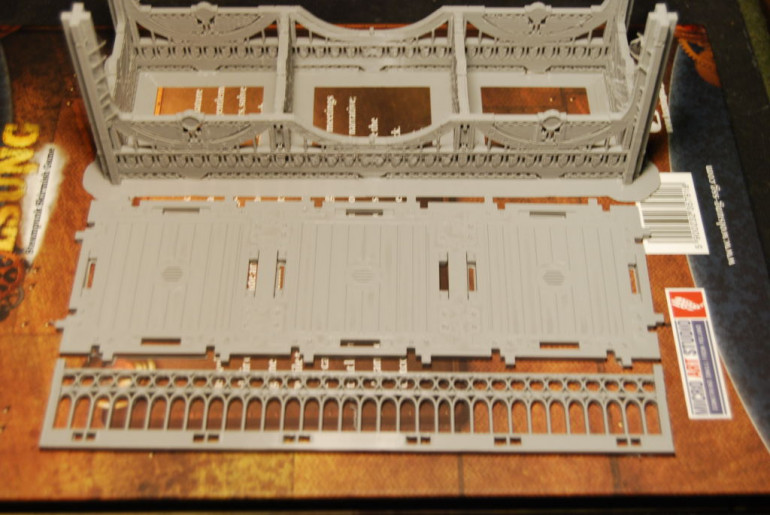

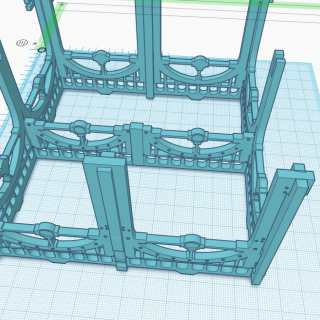

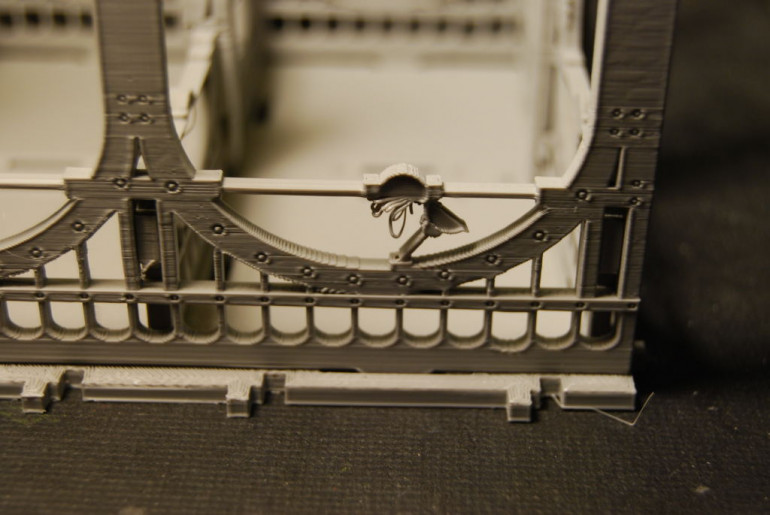

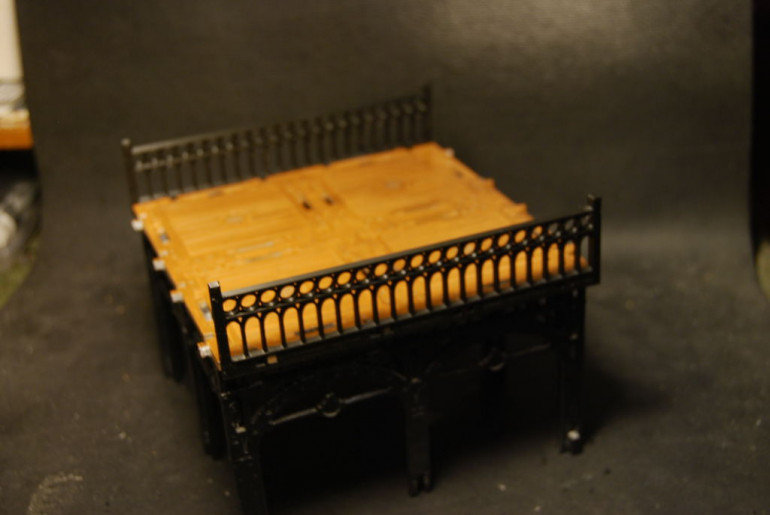

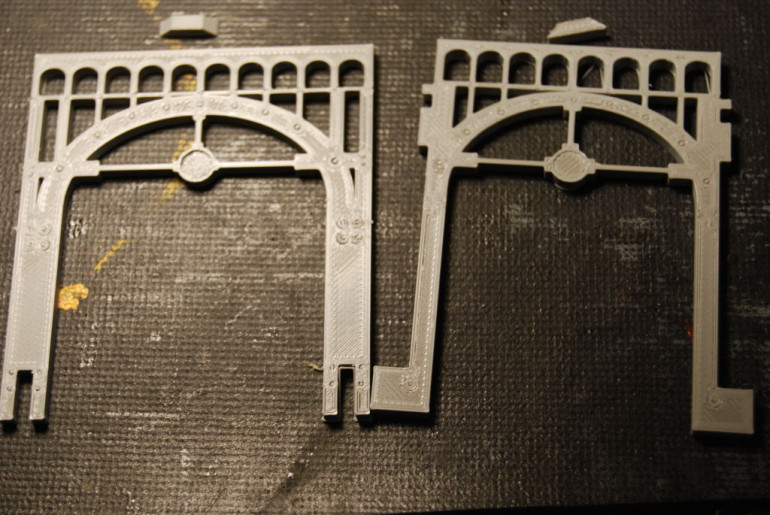

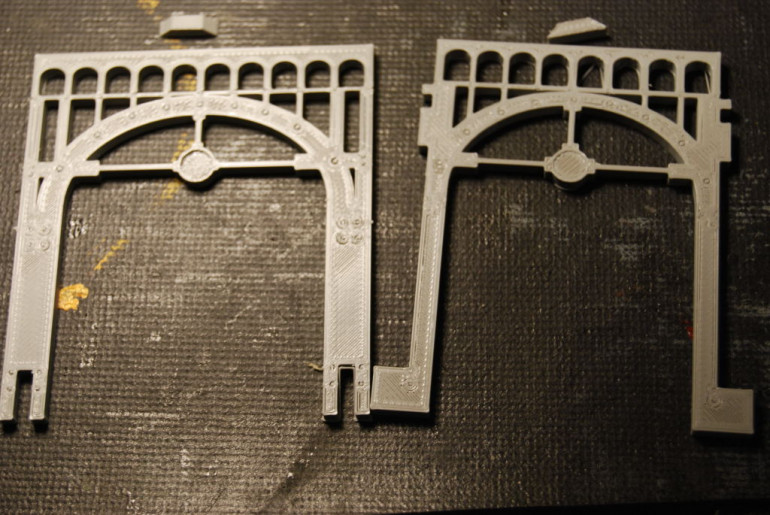

The test print has issue with slotting tabs at the top not being imbedded into the arch. so it was printed separate from the body. . Easy fix :). Also i dont like the texture of these prints, FDM printer dont print well flat.

The test print has issue with slotting tabs at the top not being imbedded into the arch. so it was printed separate from the body. . Easy fix :). Also i dont like the texture of these prints, FDM printer dont print well flat. The next test print was vertical with 4 side meshed together. I had some issue with print breaking at a very weak point and i would correct this by printing with supports in the future.

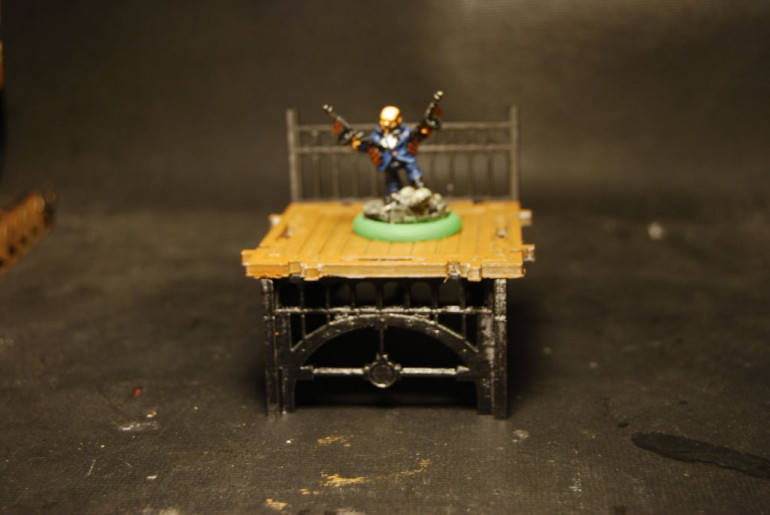

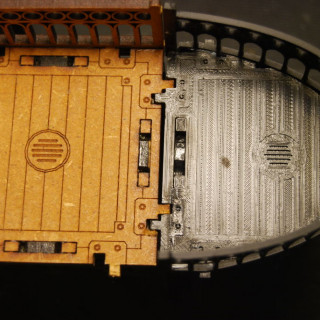

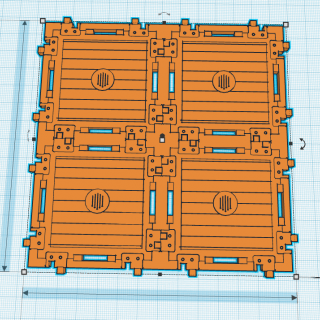

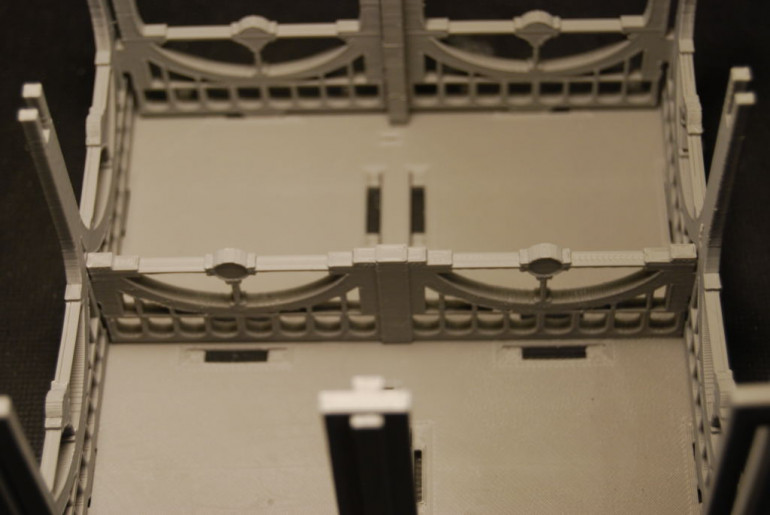

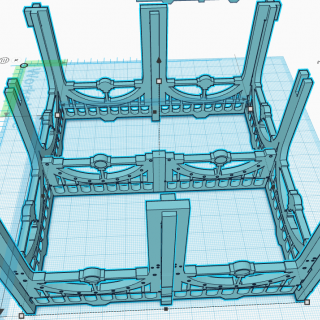

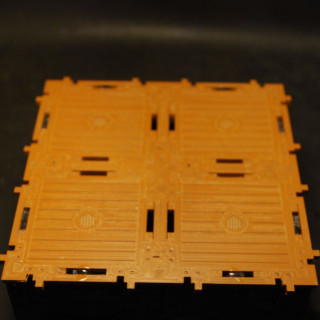

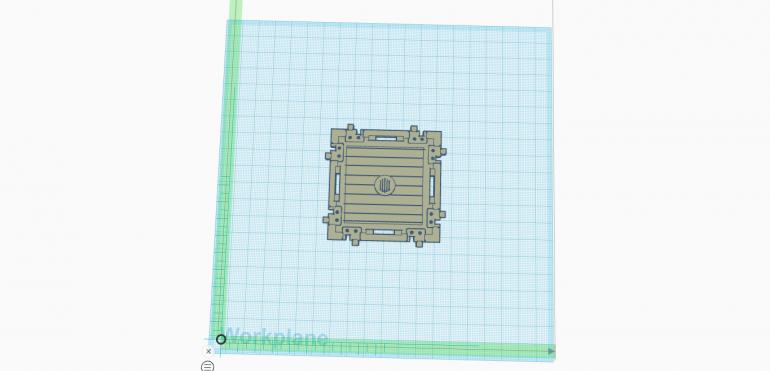

The next test print was vertical with 4 side meshed together. I had some issue with print breaking at a very weak point and i would correct this by printing with supports in the future. Next file i printed was for the deck that adds to the top. I printed this file vertical and it take about an hour longer to print and the smooth texture is not as good as printing it flat.

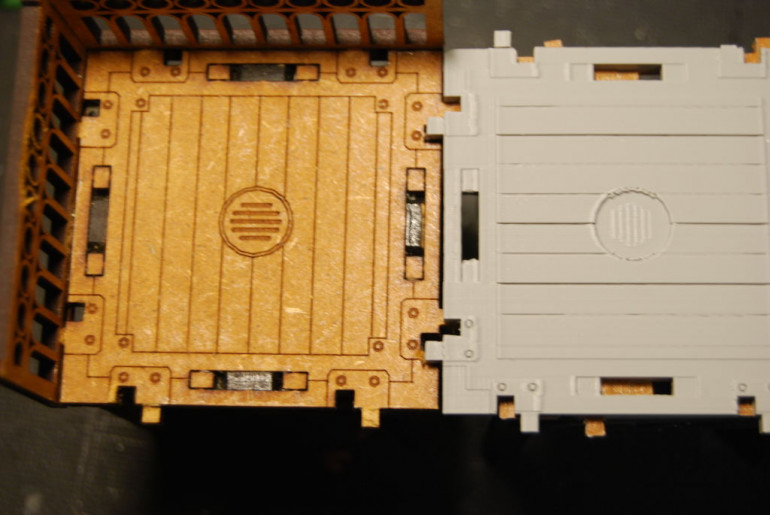

Next file i printed was for the deck that adds to the top. I printed this file vertical and it take about an hour longer to print and the smooth texture is not as good as printing it flat. oops my measurement is off by about 3mm. notice one of the tabs in the top right corner was broken off when i test fitted with an other 3d printed deck i made . This tight fit will bite me in the ass later :).

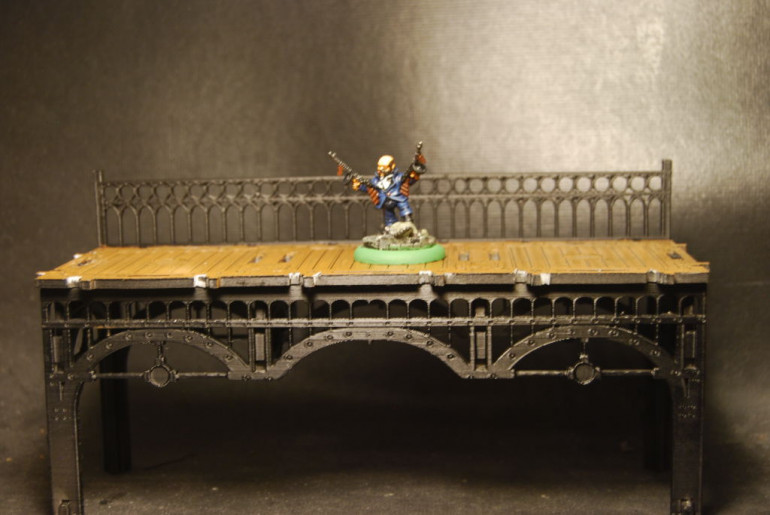

oops my measurement is off by about 3mm. notice one of the tabs in the top right corner was broken off when i test fitted with an other 3d printed deck i made . This tight fit will bite me in the ass later :).I spent the whole weekend editing and printing my old files and i finally got a matching walkway. I found out the tight fitting tabs are damaging my MDF terrain from Micro Arts Studios but when i remove about 1 mm from each side it became to loose to hold together. My logic at the time was it better to have a tight fit than a loose one. Oh boy that cause alot of extra work fitting parts for me.

Resurrecting

Looking through the files i made in 2018 for some raised walkway for Wolsung look promising .