Manda’s (Amachan) RC Adventures

Recommendations: 447

About the Project

This project follows along my adventures of getting into the world of RC crawling.

Related Genre: General

Related Contest: Spring Clean Hobby Challenge (Old)

This Project is Active

RC Truck Spring Cleaning Day 6

I got the motor and gearbox assembly all back together, lubed up and ready to go.

My RC care package from Finland has arrived!

I got a new spur and pinion gear, new bearings to replace the scruffy ones I found earlier, new shock oil to rebuild the shocks and make them a bit stiffer, XT60 plugs to get rid of these dreaded Deans T-plugs that I really start to loathe with a passion and some additional accessories.

RC Truck Spring Cleaning Day 5: Impatiently waiting for replacement parts to arrive and finding random things to fix in the mean time....

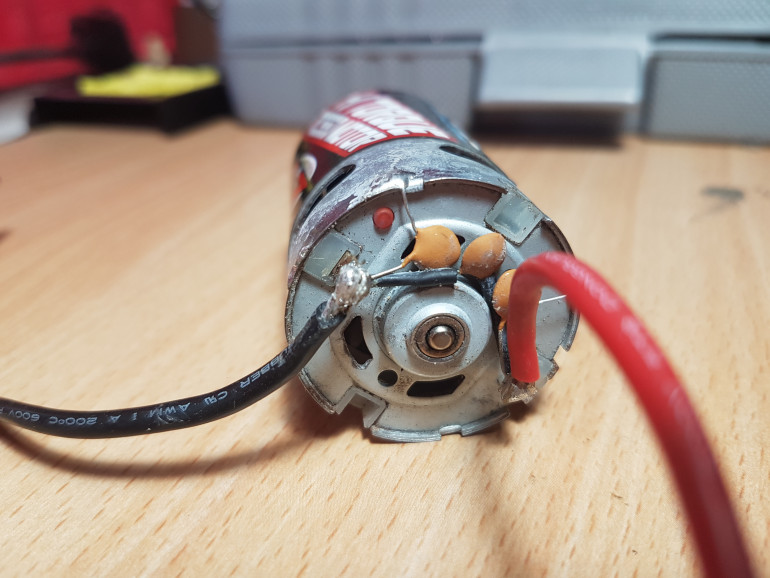

One thing that always bothered me is that the motor seemed to run smoother and faster in reverse and that there was a red dot thingy, not a light, where the black cable was soldered on. So I decided to de-solder both motor wires and re-solder them on the other way.

This Really Grinds my Gears....

I went out driving near the dunes yesterday and 15 minutes in this started happening….

You can hear the motor still turning and the drive shafts stop, this is a breakage in the main gearbox, most likely the spur or pinion gear connecting to the motor.

After taking it apart it became obvious that the pinion gear (small) had lost most of it’s teeth, the spur gear (large) however looked like it still had all of them. On closer inspection though, they are also ground down a bit shorter, you can see the splinters of the gears in the dirty lube on the side of the casing.

You can’t blame this on bad maintenance or that I put it back together incorrectly when I took it apart last. I had a picture of the pinion running the spur gear from then and you can see the pinion’s gears are already mostly gone. Somehow due to me being fairly new to this I missed this and thought it was fine. Learning along the way I suppose.

Before my car started grinding its gears I did get a nice picture though, so there is that to enjoy. Now it is waiting for replacement parts and then we continue the spring clean or spring repair updates for my RC truck.

On a side note, I did fix the rear light on my RC truck…

Exhaust problems on an electric RC car...

While driving around yesterday and rolling around on the ground, some damage happened to the exhaust stack on my car as you can see in the picture above.

It didn’t take long before it broke off.

For a while now I have been thinking of wanting to change the exhaust stack as I had a feeling it was going to break at some point. This kind of forced my hand in making a change.

First I removed the exhaust stack and the box it mounts on. Those aren’t glued together as they are both fixed to the body with screws. I wanted to go for a more factory stock exhaust that hangs under the body. So I sawed most of the stack off, drilled a hole and widened that with a craft knife. I smoothed the hole a bit and then blued it in the exhaust box.

And this is now the new exhaust on my RC truck.

I am aware that the exhaust might start grinding on the rear tire under full suspension compression, but I think it will be fine. I am rebuilding the shock early next month anyway and they should be a lot stiffer then. I will just have to see how it goes.

One of my favourite RC crawling spaces.

I thought I’d show off one of my favourite RC crawling spaces. It is pretty steep and the roots offer a great challenge to climb or descent and it is less than a 5 minutes walk from my house.

I forgot my actual camera, so phone pictures will have to do today which struggles a lot more with over exposure from the sunlight, but here are some more pictures from today.

I have broken it!

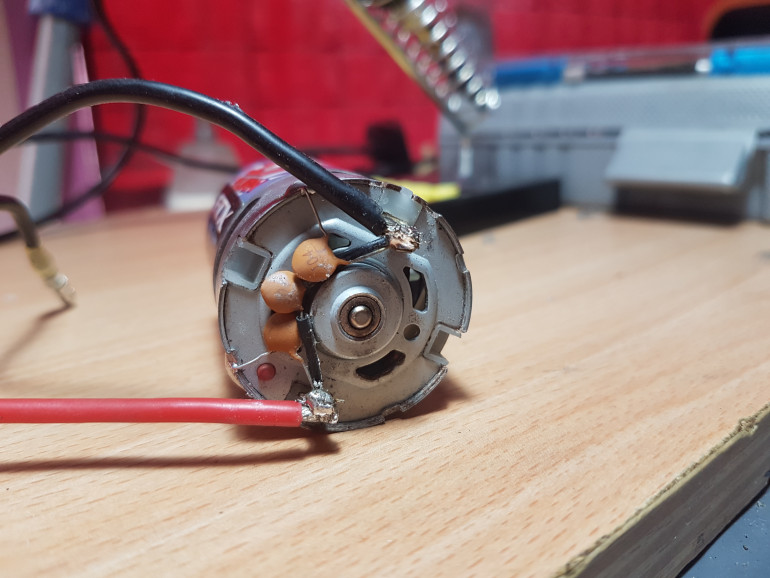

Went out driving earlier this week and one of the wires feeding power to the motor came loose. To be fair the bond looked pretty weak when I got this car anyway. So I had to buy a soldering iron and solder it back on. I haven’t soldered anything since my school days and I think I did a pretty good job, it feels pretty solid and everything works again. I am going to leave it to the soldering experts to judge my soldering and hopefully give me tips for the next time I have to solder.

Off the road again...

On a side note, I am definitely tanking the rear spare wheel off again. The centre of mass and thus the weight balance is so much better without it. It may get a lot better when I rebuild the shocks, but for now, it’s coming off.

RC Truck Spring Cleaning Day 4.

That is the front drive and steering axle done the same way as the rear axle. I found a couple more scruffy bearings that will need to be replaced. The shocks still need to be done as well, but I need shock oil first, so those will have to wait for a bit and hopefully I can get some bearings at the same time. So that’s the spring clean for now, but I should hopefully continue it next month to finish off these loose ends. In the mean time, let’s enjoy some crawling and getting it all dirty again.

RC Truck Spring Cleaning Day 3.

I was planning on doing both axles, but one axle was more work than I expected, so I just cleaned out the read drive axle today. I got all the bearing cleaned and coated with white lithium grease and put some more grease around all the cogs in the differential. Unfortunately I found 2 bearing that were rolling a bit scruffy, I don’t have any replacements right now, but I took note of it and will replace them in the future. Despite that the axle and diff are running smooth now.

RC Truck Spring Cleaning Day 2.

The gearbox went through the same cleaning as the transmission box went through yesterday and is running smooth. Now the motor is a different story. I cleaned off all the dirt on the outside and then proceeded to blow through electrical contact cleaner until it ran clear. When that was dry I lubricated the bearings with some white lithium grease, put it all back together and it is running smooth.

RC Truck Spring Cleaning Day 1.

I took the transmission box apart, completely cleaned out any dirt and old grease. I then lubricated the bearings with some white lithium grease and added a bit more grease in between the cogs for smooth running. I now have a nice clean and smooth transmission box for my RC truck.

Back into Action and Up to Date.

And now I arrive back at today, where I am getting back into action. I have tried my best to write up the whole story my truck has gone through so far, luckily I did often make pictures of what I was doing as I was planning on doing a project on this at some time. So here it finally is.

And here are some action shots from last weekend, running off the dust that had been gathering on it.

Last pictures of 2021.

Nearing the end of 2021 I fell into quite a big depression due to some unfortunate changes in my therapy. I stopped going out for a while during that time and only recently did I get back into it. So these are some of the last pictures that I made in 2021.

I climbed that tree stump!

I hump this rock. Good rock.....

Some more remaining pictures from 2021.

Dune Crawler

Going through the sandy dune areas around here has to be my favourite spot to drive. The sand makes for a really nice and interesting challenge and makes for some really good pictures.

Time for More Detailing.

With the kit came some additional detail parts, like the windscreen wipers. I also wanted to re-attach the mirrors and some other details. I painted them in the same colours as I painted the other parts before. The wheels are beadlock wheels, so I painted the outer part of them in the same chrome as I did the rest.

I put all those details on and the truck is looking great, minus the damages it has accumulated over time.

Mudrunner RC

It was a rainy day and there was going to be lots of mud, I thought let’s go and have some fun.

I was really surprised that at the end of the day the internals were still pretty clean even though the rest clearly wasn’t. When I got home, I took of the wheels and body, dropped them in the sink and rinsed them clean. I cleaned out the rest that was dirty as well and made sure nothing mechanical or electrical was wet when done.

Waiting for Components.

While waiting for all the replacement components to arrive from the last part, I decided to start painting my car. I wanted a green one anyway and I had this Model Master British Green Metallic – Gloss (2716) enamel paint that I really liked the look of, so I decided to paint the car that colour.

I completely disassembled the body, removed all the stickers and cleaned it inside and out with some soapy water.

First I wanted to clean some of the factory paint on the windows so that they were clear, for some reason factories are terrible at painting within the lines. I don’t recall exactly what I used to try and clean it, but it did remove the paint and completely fogged up the windows….. Right, plan B, black windows.

I primed all the parts with AK Interactive Primer and Microfiller Grey (AK 758).

I then coated everything that was going to be metallic with Alclad II Gloss Black Base (ALC-305-60) and then started masking everything that I wanted to say black with masking tape.

I then painted all the chrome parts with Alclad II Metal Chrome for Plastic (ALC107). Masked off the chrome areas on the body and painted those with the Model Master British Green Metallic – Gloss (2716) mentioned earlier. Sadly I ran out of this paint to get it an all even coat, but that’s okay. I painted all the other colours with basic acrylic paints by hand afterwards, I am not entirely sure what I used for what.

I applied the wood panel stickers that came with the kit to the back frame for additional detail.

I then coated everything with Alclad II Aqua Gloss (ALC-600-60) to seal it all in and then proceeded to add a bit of matt varnish to the places I didn’t want shiny.

When it all was dry I put it back together and now had a shiny green truck.

Disaster Strikes.

It wouldn’t be me if something didn’t horrendously wrong with anything expensive that I buy. So here we go. During one of the first I was distracted for a second and the car went off a bridge and into the pond at the local park. Luckily it was close to the edge, but it was still submerged more than a meter under water. I had to fish it out with a stick. I succeeded and most of the car was still working. Most of the components where waterproof after all, well apart from the receiver. They put the receiver in a (not-so) watertight box. So after I fished it out it was acting up, steering and throttling like mad. I turned it off and got it home. Sadly warranty was voided for any form of water damage.

So I needed a new receiver and I thought I’d get a new transmitter in the same process. I got the FlySky FS-GT3C with a receiver knowing that I can also get extra receivers quite easily. I am quite happy with this, it works well.

So everything would be well again I thought, so I went out a couple more times and then found out that the steering servo was acting up. I took it apart and found out that this waterproof servo was not so waterproof after all.

So I got into contact with Etronix, the manufacturer of the servo and told them what happened and asked if they knew of a way to fix it. They got back to me and said that as a good will gesture they were willing to replace it. That was great, unfortunately they didn’t have any in stock and would then be willing to send an alternative, a 6kg servo. Now the servo that was broken was a servo with 15kg pull strength, so that would have been a severe reduction in strength. I looked at their website and asked for a different one saying that I would pay the difference. So that’s how I got an Etronix ET2070, a 21kg servo for 5 pounds. It took a week or two to get here from the UK I then installed it and it worked great.

I then proceeded to add additional waterproofing to this servo using a silicone sealant for aquariums and sealed up the receiver box as well. So now on the mechanical and electrical front everything was fine again.