Its not a PUMA

The long hiatus

So it turns out the weird print bug in my previous post was the beginning of the end for my printer. It’s a story I won’t regale you with here as there is more interesting stuff to talk about ,but I’ll some it up with. Weeks of diagnosis. Heat creep. Non-original parts. Blue smoke.

On the upside. In the place where my FDM printer sat now sits an Elegoo Saturn :yay

While figuring out my printer woes I had had plenty of time to distract myself with a wish list of what might be if I got myself a resin printer and a few points considered were.

- The reduced print bed so will need to find some convenient cuts.

- The ability for finer, more detailed parts, ie. Can I make a model for a model maker?

- The possibilities of clear and translucent resins – unknown and untested

- And I thought I should remodel generally to remove a lot of the poly flats and encourage curves, upping the resolution.

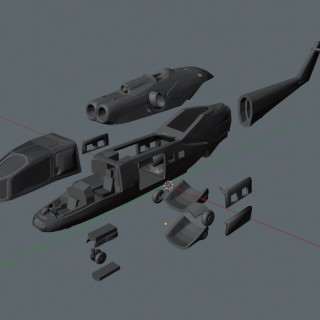

After a few sessions snatched from the daily grinds I arrived at the pic below, and felt I had a model that would give both landed and flying versions as per Battlefronts, some nice details relevant to the scale and reminiscent of scale modeling and room for some ambitious ideas such as transparent parts for glazing and doors that could be positioned open for landing and door gunners.

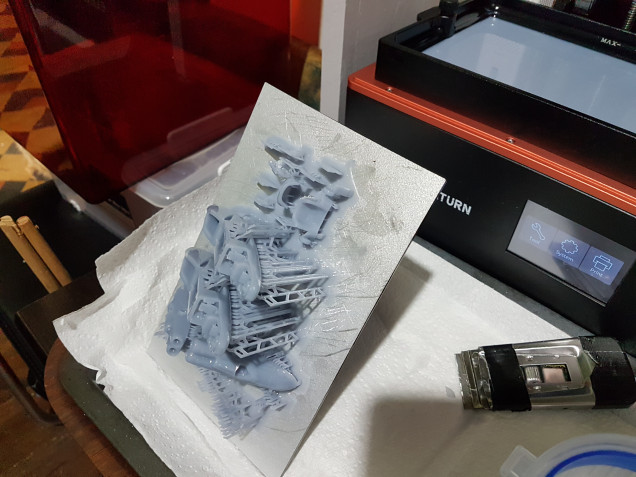

The first resin I had tried on my printer was the Elegoo water washable clear blue. (Which I found good, had no real complete fails, just my lack of understanding of small parts. But a lot of contaminated water)

So I while printing tigers, pz4’s and Hanomags amongst other things I put down my Mi-24 glazing components to see how they would go

The initial result left me feeling a bit suspect.

But after a light spray of polyurethane clear gloss (as used on furniture) I think it shows a fair bit of promise. And at this scale, promise is all I’m after. The Hind A was renowned for its glass canopy cockpit and all I’m really after is the knowing that there is detail beyond subject to the suns rays. Also I need to balance the minutia at 1/100. (To me, as an architectural technician that’s pretty much an oxymoron).

The second resin I’m playing with is eSun PLA-Bio and this project is my first print with it

I followed the esun exposure times for the Elegoo Staturn but have slowed my printer down mechanically for all prints to allow for patient peel times. I generally print only Sat and/or Sun nights so can afford a little extra time on my prints and have time for the (hangover) clean up.

Leave a Reply