Raiding the Dusty Wastes

And Now for Something Completely Different

There are perks to working in a sheet metal shop; notably, there is no cost for scrap materials I can claim as my own that the shop is going to throw out or there is negligible cost for due to sheer amount of inventory.

I had gotten the rough estimate of what size I wanted my tray to fit inside the plastic bin and then did a quick measure when I was at work. I gave a little space near the sides as I’d need some room for my hands to grab handles I’d later attach as well as the fact that the corners are rounded inside. The 24 gauge sheet steel was small enough to handle without needing huge sheets. This image comes after the initial cut that separated it from the 29″x60″ sheet and the following shear of the 29″x15″ to the final 24″x15″. I didn’t give it the extra 1/4″ that I had measured as I figured there should be some tolerance to the plan. Having worked with a friend who produced parts for ICBMs (yes, real nukes) I know there’s a hell of a lot less at stake here as well as no need for a micrometer (despite the thought it might be cool to have).

With a bit of plywood lying around from assembly and the sheeting that comes with material it seemed perfect as I was allowed free rein to what would otherwise become scrap and trashed. I picked out the 1/2″ thick material and cut it to size.

I fixed the steel sheet to the plywood with 1/4″ stainless steel self tapping screws that are used regularly for work in roughly a manner that would be even and not allow the sheet to pull up from the wood. The sides were left open as the handles would secure those areas.

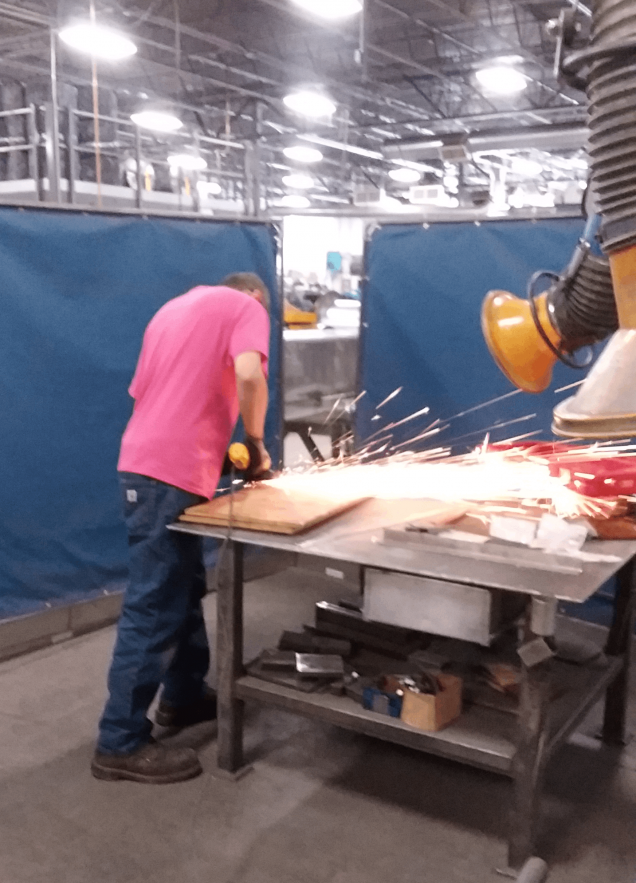

I was irritated by how the taps for the screws passed through the boards entirely and how thy would end up scratching whatever surface they would sit on so I decided on going to the welding area and pulling a rotary tool with cutting wheel. It was so fulfilling to let loose and have sparks fly around as I destroyed the ends of the screws to make them flush with the bottom of the plywood.

Since its boobie appreciation month work has had us dress up in pink shirts for Fridays. Really, do we need a month to say we like boobs? I think there are other areas of interest that should be given attention but I don’t believe that neither HR nor society at large would be so keen on hearing out my thoughts.

I was none too thrilled about the fact that the rough edges and bottoms of the boards were raw. I thought that there should be some more work put into the products I would be using. I was going to be proud of what I made and the little effort of sealing the wood with polyurethane varnish was just the thing. A little paper that would otherwise be used for interior job sites went down to protect the shower. The wood, having spent many months in a storage trailer, sucked up the sealant readily for the one coat and made my life easy to avoid much cleanup.

![TerrainFest 2024! Build Terrain With OnTableTop & Win A £300 Prize [Extended!]](https://images.beastsofwar.com/2024/10/TerrainFEST-2024-Social-Media-Post-Square-225-127.jpg)

Leave a Reply