Titans of Minerva

Terrain Thoughts

Adeptus Titanicus needs its terrain, both from a game play and immersion perspective. GW brought out its Civitas terrain with and in the Grand Master launch box and added to it since. If I were to start out again with AT I would almost certainly use 8-10mm MDF terrain of which there is a lot out there now and at the scale its pretty easy to work with.

On the plus side the GW terrain looks great, is pretty modular and in terms of sizing is very much tailored to the needs of AT. Building up levels in buildings works out in knight and then titan-sized increments. On the downside its expensive and if you do want to build some of the spectacular looking larger structures its going to cost more than a 40k Knight in parts.

As I had a Grand Master box and terrain was one of the first things I assembled way back I am going to stick with it now and slowly overtime build up a table’s worth. As the paint scheme will be identical to my 30/40K terrain in my mind its all part of my Warzone Minerva in my mind.

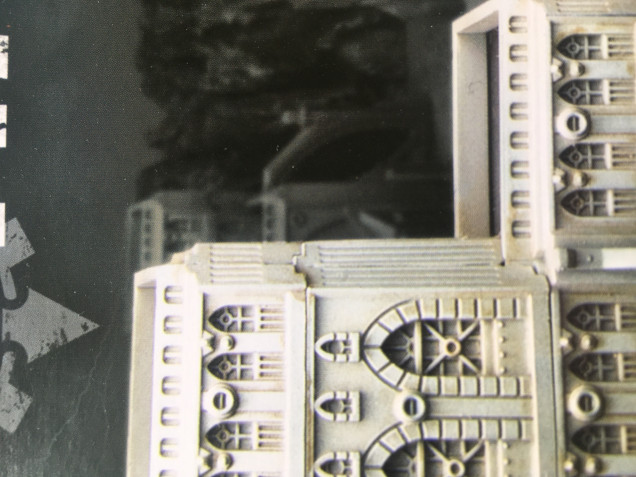

Cost isn’t though my main issue. This modularity has come about from GW’s embracing of CAD design which has worked really well at the 30/40K level to give this endless toolbox. At the AT level it still works, but the design doesn’t take into consideration that the tolerances at this far smaller scale are much less. Being even 1mm out cascades into significant gaps halfway down larger buildings.

Not even the terrain on the GW box itself is properly assembled and fitted!

Is it important? Well everyone will have their own milage on terrain, but for me if I am going to spend that much on it I want it to look good.

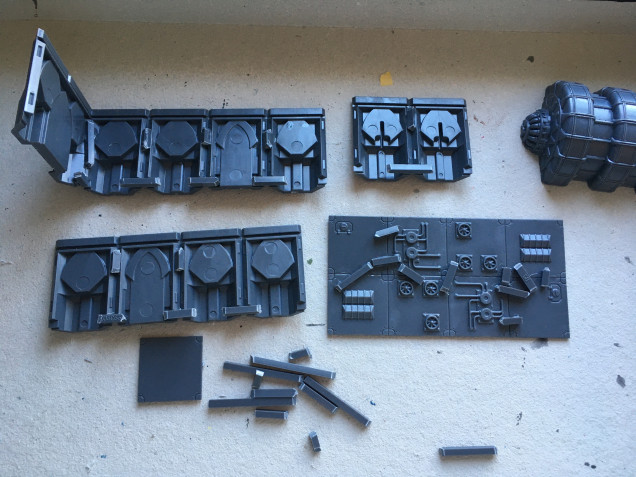

Having frustratingly got through the terrain of the Grand Master and an extra Civitas box – to the point I really did not want to continue – I decided to change my approach. In order to get the precise fits needed I have gone over to reinforcing all the connections and glueing in extra supports. The downside is it takes 4-5x longer to do it this way as each panel needs to be glued in separately and set before the next.

The upside of sorts is that doing this I can recycle all of the original sprue material as it takes all the longish bits from a Civitas frame to support a structure made from the wall panels.

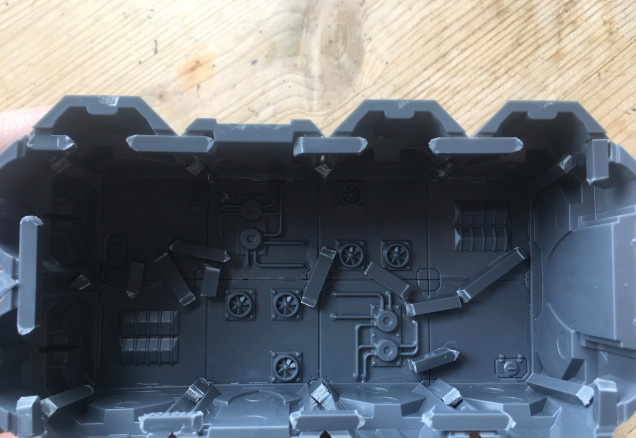

And the end result is with all that patience a near perfect fit is possible. I think there was only a tiny mistake on the building below. It doesn’t thrill me to have to take this approach and time, but its the only way to get the end equality I am happy with.

Leave a Reply