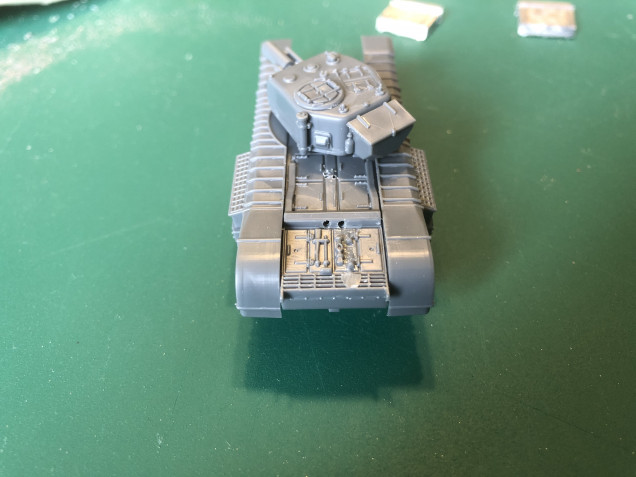

How to be an Armoured Farmer, building Hobart's Funnies in Glorious 15mm (and maybe 28mm if they arrive in time!)

Final touches

Again, prepping for the wading ducts to be added later I drilled four holes for the wire stays. These are one for each of the side air intakes and then two for the rear duct. The eagle eyed will see that they are located in the middle of the engine deck. I drilled them using a 0.5mm dia drill. I also drilled out two 1mm dia holes in the exhaust manifold in order to take the specially adapted exhausts that were added to the the wading tanks. This is a good indicator for what AVRE's were fitted with wading ducts when looking at reference photos, as the duct wires were fitted with small explosive charges so the duct would drop away once ashore. the exhaust however required unbolting, something which, in the heat of battle, one was not in a rush to do!

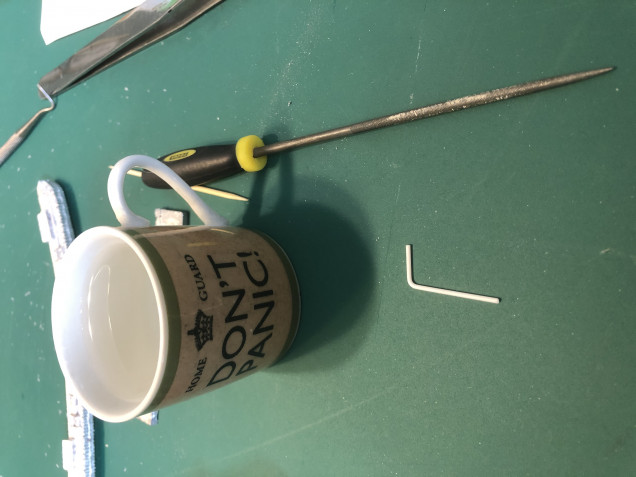

Again, prepping for the wading ducts to be added later I drilled four holes for the wire stays. These are one for each of the side air intakes and then two for the rear duct. The eagle eyed will see that they are located in the middle of the engine deck. I drilled them using a 0.5mm dia drill. I also drilled out two 1mm dia holes in the exhaust manifold in order to take the specially adapted exhausts that were added to the the wading tanks. This is a good indicator for what AVRE's were fitted with wading ducts when looking at reference photos, as the duct wires were fitted with small explosive charges so the duct would drop away once ashore. the exhaust however required unbolting, something which, in the heat of battle, one was not in a rush to do! As a practice I tried to bend some styrene rod into the shape of the exhausts. whilst it worked ok using boiling water, there was a tendency for it to straighten out again and lose the 90 degree bends. I have therefore decided on 1mm brass rod instead and shall nick the wife's jewellery pliers, as they are specially made for bending radii.

As a practice I tried to bend some styrene rod into the shape of the exhausts. whilst it worked ok using boiling water, there was a tendency for it to straighten out again and lose the 90 degree bends. I have therefore decided on 1mm brass rod instead and shall nick the wife's jewellery pliers, as they are specially made for bending radii.

Leave a Reply