Hot wire cutter from scraps

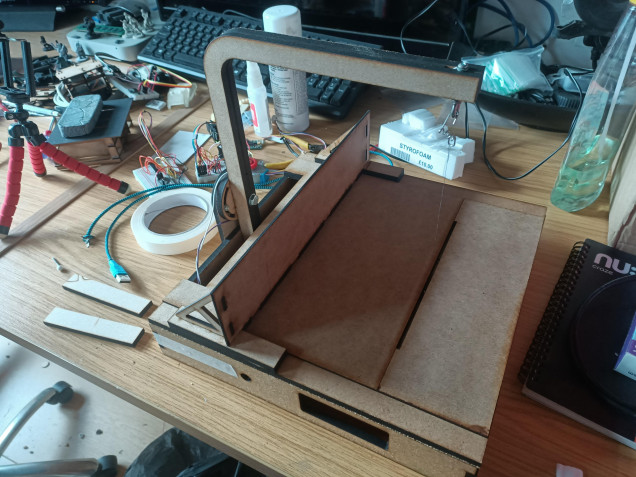

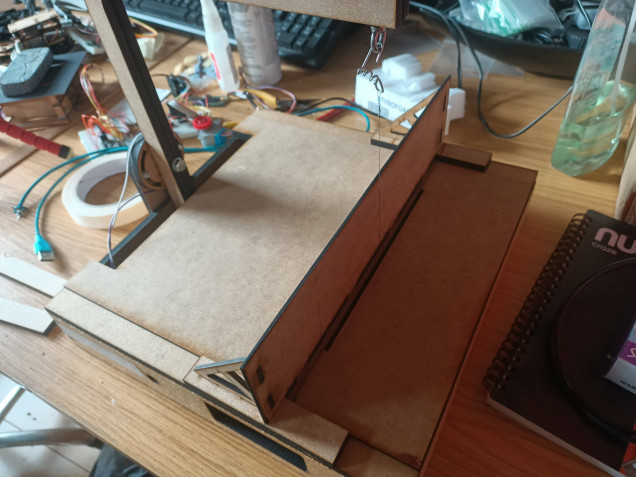

Building the table

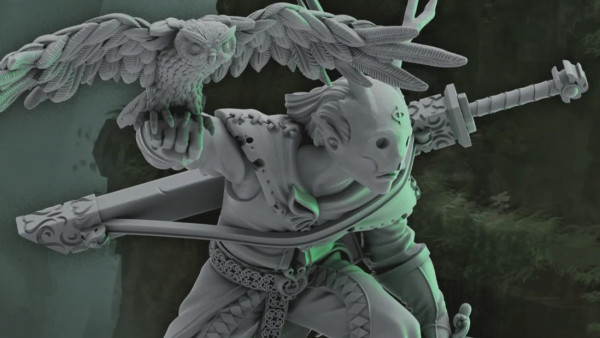

There’s not really much to say about this – the table is simply a square (290mm along each side) with a 3mm slit (for the wire to come through from underneath) and some 60mm high sides glued onto the underside.

Rather than just nail the wire frame onto the base, I used a centre-pivot to allow the frame to be angled up to 45 degrees (in both directions).

The top layer is a duplicate of the main tabletop, but reduced by 20mm top and bottom. This creates two “runners” into which I could drop the sides of a sliding “fence” (or guide).

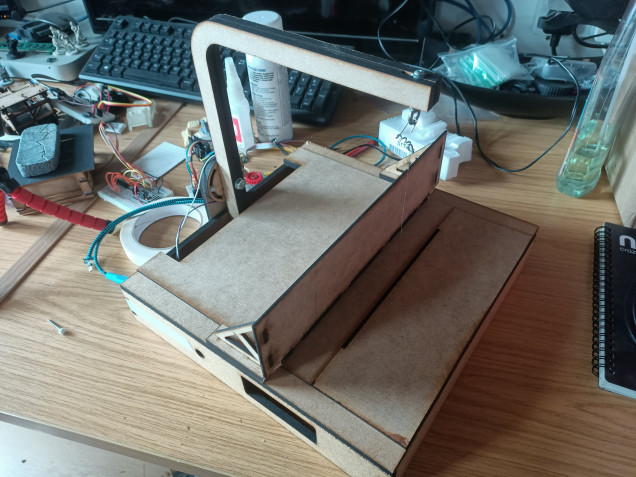

Everything was coming along swimmingly.

Until I came to actually use the device (some of you may already be one step ahead here). When I came to push my block of styrofoam along the fence guide, the “legs” in the gutters got in the way!

Now, I should really have re-designed and re-cut the fence. But I was so keen to try the machine out, I just hacked at the fence with a stanley knife!

I doesn’t look pretty. But it does the job!

Leave a Reply