Red Rocket 3D Printed

The Ups and Downs of 3D Printing

Well, it’s been a mixed bag of results.

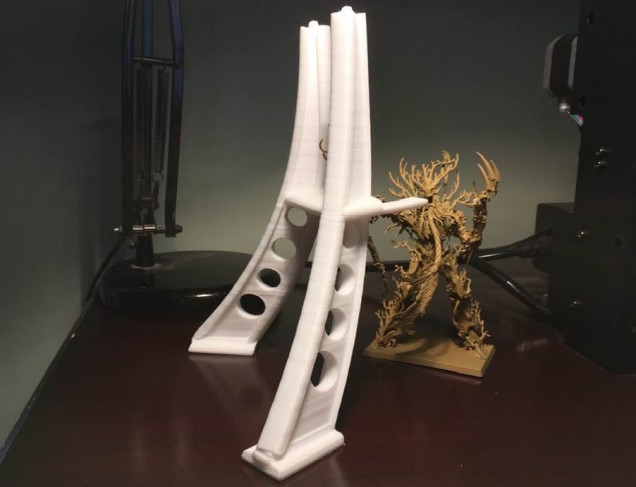

The first girder came out fine (The Treeman Supports Girder A).

Now… as the title says ‘the ups and downs of 3D printing’.

As well as Girder A went, Girder B has been a nightmare.

The print failed 4 times (below are a couple of the fails)

Once a support failed; and the other three times the actual Girder itself detached from the build plate (the last time 6 hours into the print).

I decided to stop trying to print the model and changed to another model I have previously successfully printed. This was in order to see if it was the settings and/or support that was the problem (and that failed too by detaching).

When this happens there is usually one of several possibilities.

- The Build plate is not at a sufficient temperature

- The Plastic melting temperature is too low/high

- The Build plate is no longer correctly aligned

- There is insufficient model and/or support touching the Build Plate.

I checked all of the above and it was none of those.

I was a little perplexed, and must admit was at a loss for a time. So I did what I normally do when me and technology have a difference of opinion. I walked away and did something else (more on that in the next post).

About a day later it occurred to me that I had greased the two runners where the printer head travels side to side. And I had a ‘I wonder if’ moment.

So I took a piece of plain paper and placed it on the build plate and gently rubbed my hand over it. There was the problem a small bit of grease was on the build plate causing the print to lose adhesion.

I cleaned the grease off with isopropyl alcohol and tried to print a test piece…It worked! Cue the music…

I will get back printing Girder B soon. Until next time folks.

Leave a Reply