Spring Clean Challenge: Developing WWII infantry for 3D printing

Small Soldiers

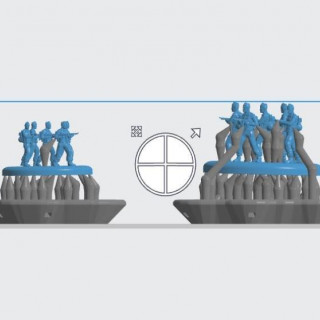

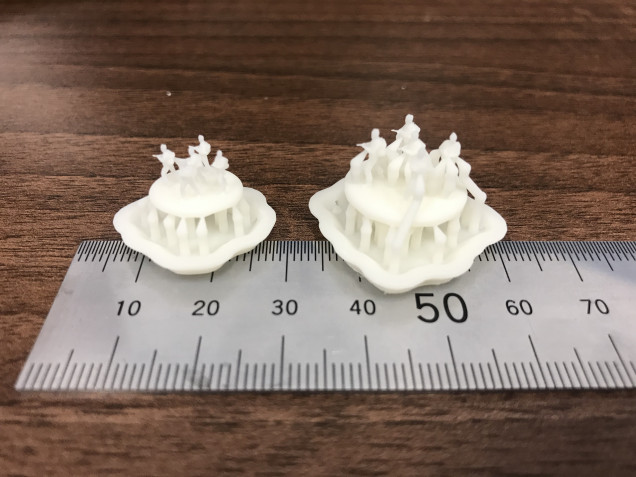

The next step was to export the commando base from Zbrush as an OBJ file to be loaded into a slicer program (in this instance Preform). I decided to print another scale comparison so I made the first base of figures 6mm as well as a duplicate scaled to 8mm.

I positioned the first commando base in the slicer program and tried several different orientations in order to find the position that resulted in the fewest support struts being generated. As I had hoped, this turned out to be base down. This was ideal as it meant most of the supports would be beneath or against the base where they could more easily be removed.

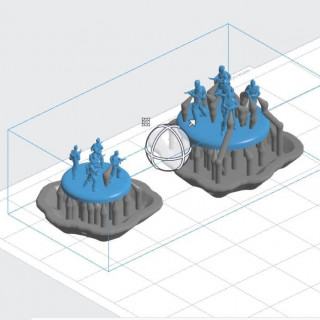

I set the printer to the smallest layer size available (0.25mm), to get the cleanest print possible. Within a couple of hours I had the above prints out. The rafts protected the delicate models as I removed them from the print head to be cured. Interestingly the 6mm base required fewer supports, resulting in even less clean up. The 6mm also doesn’t seem to have lost any detail compared to the 8mm, although at such sizes it’s hard to tell for sure.

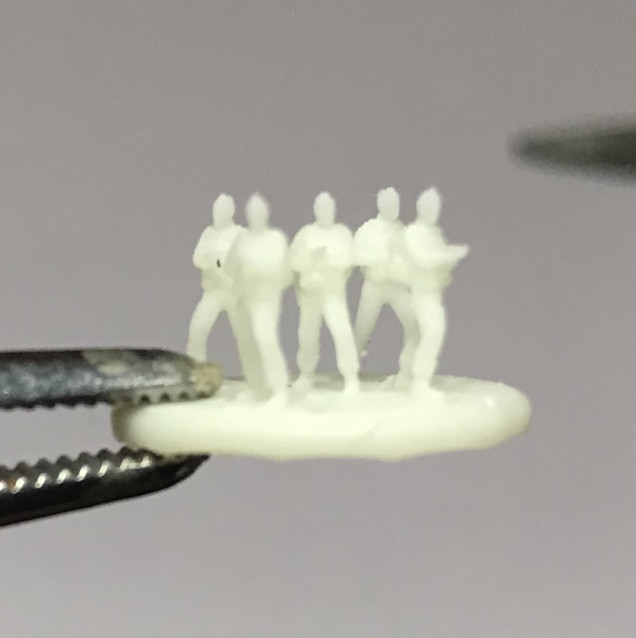

Unfortunately once again the 6mm figures broke at the ankle during handling. This kind of resin is hard and therefore brittle at such small sizes.

The 8mm faired a little better and I managed to snip away the supports without damaging the figures themselves. Hopefully you can make out some detail from these images. I have to say I’m pleasantly surprised by the results but the fragility of the figures is a bit of a problem. The guns have all printed this time although the barrels are pretty insubstantial on most of the figures. The Thompsons definitely need to be scaled up again, requiring a further increase in bulk. I think the easiest fix is probably just to inflate the whole model again, this time I’ll try 5% rather than 2%.

Leave a Reply