Spring Clean Challenge: Developing WWII infantry for 3D printing

Eureka!

I didn’t see the point in taking a neutral pose forward as a test print so I figured I’d have another crack at posing. After a little homework I found out about a function callet Transpose Master. This operation drops the working model (referred to as a tool in Zbrush and often containing multiple sub tools), to a low polygon count in order to facilitate faster processing.

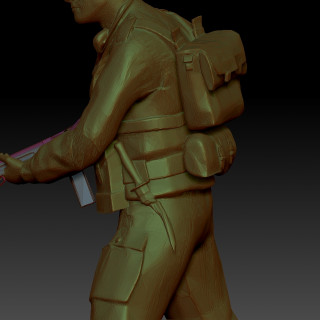

I also constructed a new rig as this was a process I could carry out pretty quickly now (10-15 mins). As soon as the new rig was bound to the soldier mesh I noticed big improvements. The lag I had suffered previously was now gone and the model moved freely. A further benefit of using Transpose Master was that I was able to bring the Thompson along with the model as a separate sub tool (I was only able to use a single sub tool with the previous rigging method).

I was able to create this pose in around 20 mins. It’s not perfect and you can see in the below images that some areas, especially the knife and Submachine Gun, have distorted very badly.

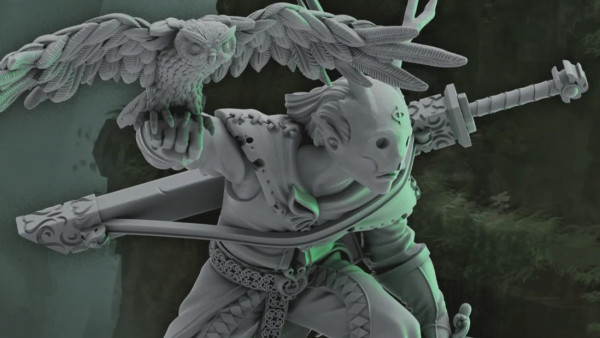

I had anticipated some clean up would be required to the posed model so I had replacement parts standing by. I swapped the Thompson and knife for undistorted versions from my earlier clean up and touched up the modelling here and there.

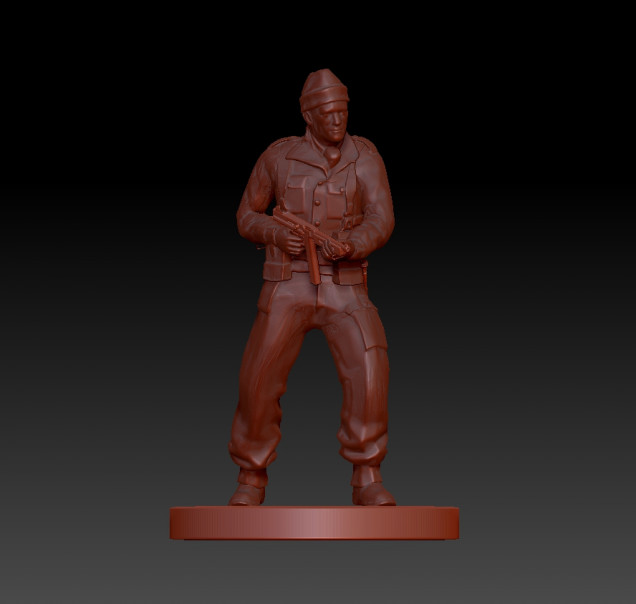

With the addition of a simple circular base my soldier was beginning to look a lot more like a gaming miniature.

Before exporting the model for printing I checked over the mesh. Specifically I needed to ensure that the model was ‘Water Tight’, which is to say that there were no holes into the mesh and no areas of hidden topology within the model. Once I was happy that the mesh was fit for printing I scaled him to a height of 6mm from the top of the base to the dent in his woollen hat. As I had conducted sculptural work on the model again the poly count had crept up to around 2 million so it was necessary to Decimate once more before exporting my Commando as an OBJ file.

Leave a Reply