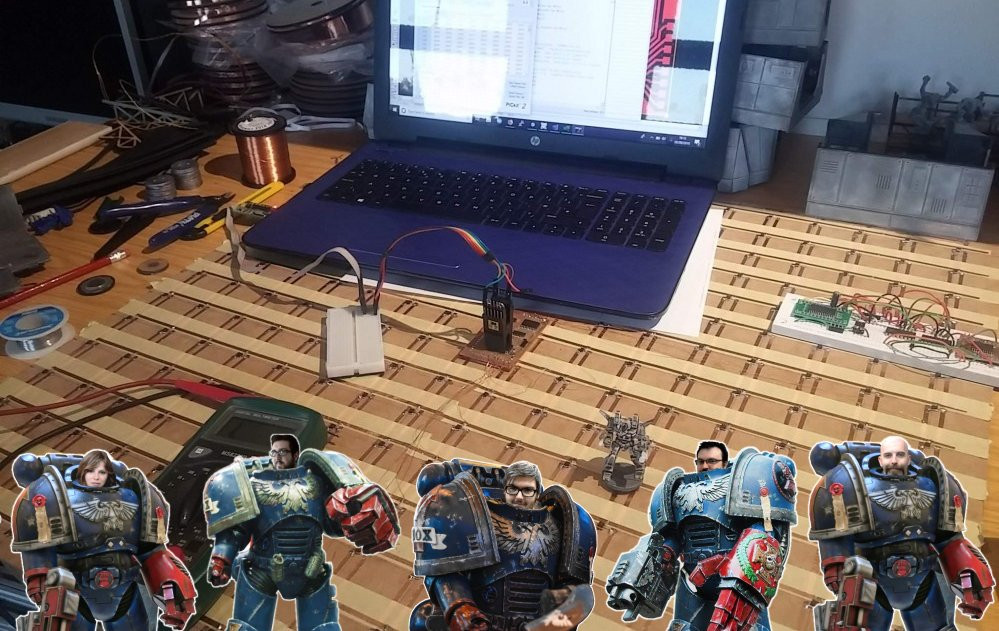

Interactive tabletop playing surface (Space Hulk Hobby Challenge)

Large format multi-purpose skirmish panels

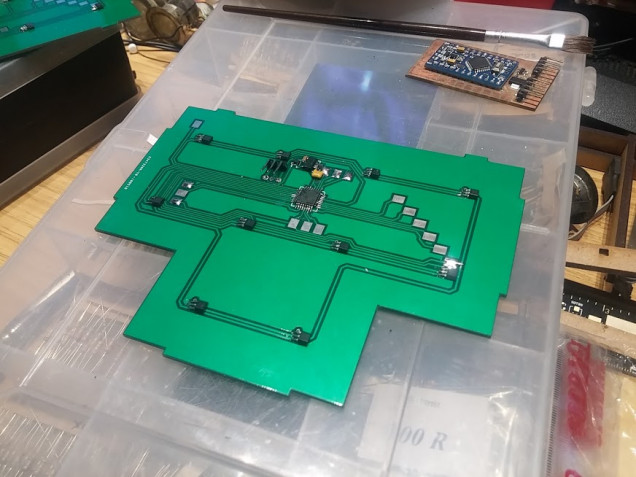

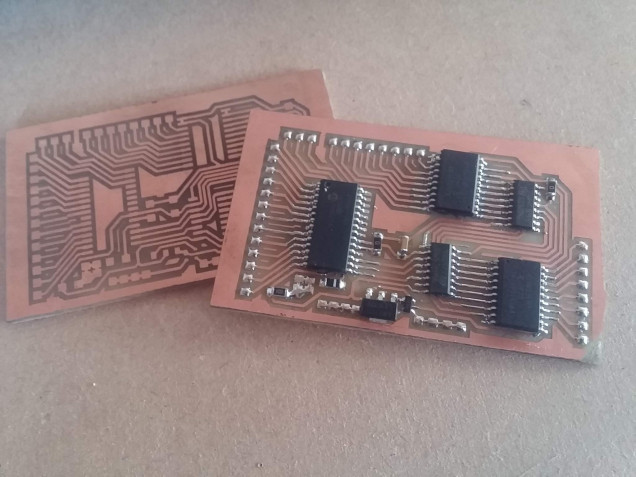

Originally I made my Space-Hulk-alike dungeon from multiple sections, each with a manufactured PCB in the base (PCBWay does relatively cheap circuit boards and even cut them to shape at no extra cost).

Each piece was not more than 140mm x 140mm.

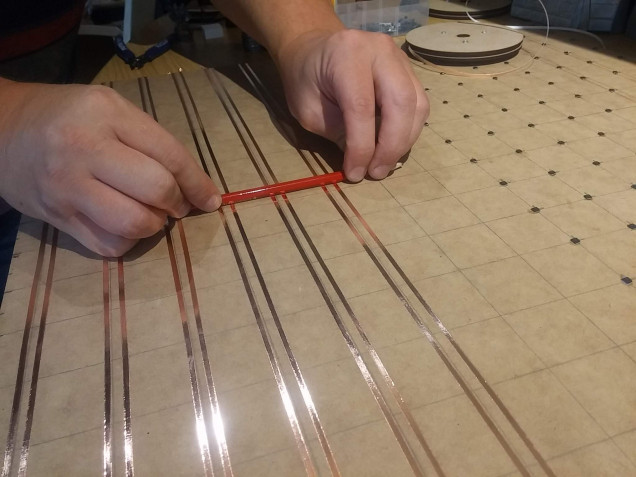

My new, multi-game panels are going to be 610mm x 610mm (simply because thin mdf sheets are readily available in 610x1220mm so are easier to cut to size). But the price per PCB for a massive 2ft square is about £45 per circuit board! That’s before shipping, before tax and import duty, and unpopulated (i.e. not including electronic components). That’s just too spendy!

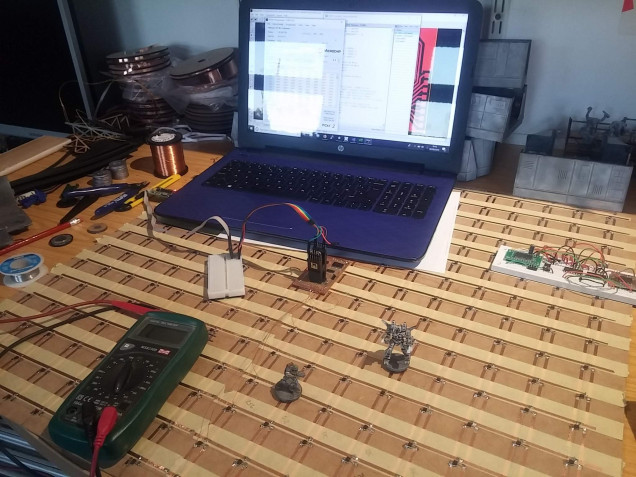

Using strips of copper tape (and masking tape to avoid unwanted shorts in the circuit) and some locally sourced mdf I managed to build a base ready for my hall sensors for about £3.00 all in. At least the project was starting to look feasible once more!

Etching your own PCBs at home isn’t as difficult as you’d think.

Simply print your (mirrored) design onto magazine paper (the cheaper the better) and iron it onto some copper clad board. Unless, of course, you have (or have access to) a laser cutter. Then you spray the board with matt acrylic paint, and etch away the gaps between the traces.

After throwing the whole lot into some warmed-up Ferric Chloride, it’s just a matter of waiting. I measured it as “the time it takes to make a drink a brew with two digestives”. About 15 minutes.

Once etched, some steady-hand soldering is no more difficult than getting the eyes right on one of your Cadian troopers – sure, it’s tricky, but not impossible.

My original multi-part dungeon used an Arduino in the centre of every single piece. Because the entire map was based on 4×4 sections, this meant that the microcontroller didn’t have to do too much work.

On these larger format panels, there’s a massive 16 x 16 grid. That’s 256 sensors! A simple 8-bit Arduino simply isn’t up to the job on its own. So I went back to my preferred platform and used one of Microchip’s PIC microcontrollers, a couple of shift registers, some current source drivers, and a lot of multi-plexing trickery in code.

To date I’ve got the panel reporting the square number whenever a miniature (with a magnet in the base) is placed (or removed from) a square in the grid of sensors. Now to get the data into some kind of app…..

![TerrainFest 2024! Build Terrain With OnTableTop & Win A £300 Prize [Extended!]](https://images.beastsofwar.com/2024/10/TerrainFEST-2024-Social-Media-Post-Square-225-127.jpg)

Leave a Reply