Terminator II Inspires Carbon3D To Speed Up 3D Printing Process To Minutes

March 17, 2015 by brennon

It might sound like it's something out of a Sci-Fi movie, and it kind of is, but Carbon3D have stunned the 3D printing world with the announcement of their new technology that makes 3D printing take minutes instead of hours. Check out the video above and you'll be gobsmacked by how quick this is...

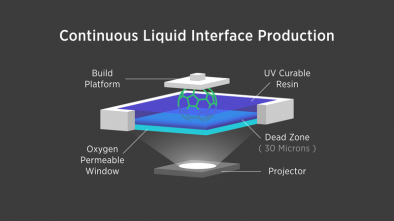

Instead of the 3D printer laying down layers one at a time this new continuous liquid interface allows you to draw the object out of a bath of resin using the light to build it as it rises. As you can see by the video above it's insanely quick and the detail looks just as sharp as the traditional (wow, traditional already) mode of 3D printing we've seen before.

Of course a lot of people have already talked about the scope for mass producing good using this quicker method but for us as wargamers we face an even cooler prospect. Instead of having to spend hours at the 3D printers your batch of models could be ready in just a few minutes and if this got into homes it would be even quicker for the consumer.

As they showed above when pulling out the model of the Eiffel Tower you could easily build terrain with this and models could be made, for board games especially, in pre-coloured form a lot quicker than normal.

To think that Terminator inspired this!

"Instead of the 3D printer laying down layers one at a time this new continuous liquid interface allows you to draw the object out of a bath of resin using the light to build it as it rises"

Supported by (Turn Off)

Supported by (Turn Off)

Supported by (Turn Off)

Wow

Hasta have a printa, baby

THATS AWESOME!

She would NEVER let me buy that! Fantastic though. D.x

Funny, I saw another company do something similar back in January…

https://www.youtube.com/watch?v=mkLNnOGWRFc

I was saving a deposit for a mortgage but I guess one of these would be even better!

Yeah you could build lots of tiny houses instead 🙂

the way things are going. Man this is realy a golden age. Hope i will live long enought to see all this awesomeness and be abel to use it

With a big bed on this – a whole faction could be drawn up at once – very excited!

This method of printing isn’t new, it’s just nicely presented in this video. My article discussing this should be up soon! One of the problems with this method of printing is that you have to keep everything spotlessly clean in order for the expensive liquid resin to be cured by light.

Here’s a video of someone experimenting with this kind of 3D printer:

http://youtu.be/s8zwlbs_QvM

Spotlessly clean… hmmm. Might not be the printer for me then. My house sometimes looks like a warehouse, with all the boxes and toys lying around.

That looks amazing! I’m still wondering how the price compares to other printers and materials. And can this process be done at home or is it too dangerous or complex?

There are cheaper and smaller versions, which I would suggest for our hobby:

http://youtu.be/wZkx4KRmHl8

But I still think this type of printer is not quite ready for home use. The price of the resin is still slightly too high, and the wear / cleanliness on the device means it is not a long term device.

Here’s another cheaper one:

http://youtu.be/aCbNua94Zfc

[not a long term purchase]

All this advances in 3D printer technology are just astonishing, not just for wargaming. It is and will be the revolution of this century.

Quite interesting, we will see.

looks amazing.

Hhhhhmmmm, I think one of these will be on my shopping list in the next few years…

This thing is DLP on steroids. The build speed is nice, the lack of build lines with this process is what sells it for me. Now, if they can just get it below $10k for the printer, I am in….

The speed is nice but its not the biggest thing that concerns me about 3D printing. What is is the resolution. Normally the print heads used in extruded or UV lasers used in resin printing creates the lumpy look. This method projects the light so it should be able to create very high resolution objects.

I would disagree. Yes, the extruded filament printers wouldn’t be as accurate as this, but the laser printers like the Form1 would be more accurate. They use the same blu-ray lasers that are used to read off of discs. The main benefit of using a projector is that they seem to be getting shorter print times, but I doubt the accuracy.

100% agree… FDM style printers are not up to the task of 28mm scale miniatures, at least not yet, the detail level and step lines are not ideal for 28mm scale masters.

The Prefactory multi mini is my tool of choice for 3D prints for this scale. Prints are expensive but far outshine services like Shapeways.

the problem with 3d printing is that i’m not a 3d artists!

So i need 3d models or an easy 3d builder…. or a 3d scanner….

all cheaper than buying the models!^^

So I guess that this prompts the next question, which 3D modelling/drafting programs work well with this style of printers. What allows you to achieve the maximum detail possible given the built style.

My article series starts on Monday!

I use Rhino for hard surface modeling and Zbrush for organics. Both programs work very well for micro details that far exceed what current printers can handle.

There are free alternatives available but I have never used them because the two programs I just listed did everything you need them to do as efficiently as possible. There is a learning curve to all 3D programs, without actual training you are likely looking at 3-12 months of pouring over tutorials before you feel confident.