From the workbench of the esteemed Horati0nosebl0wer

Just a slightly pressing issue

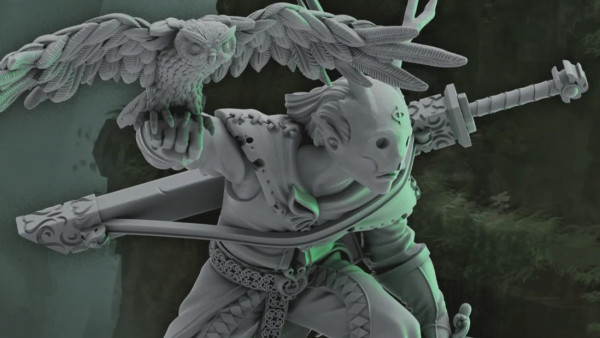

A test of Miliput black with a GSW roller on a plastic round edge 30mm base. I recommend in future using a roller on a flat surface and then a round cutter for the center. It should give more even pressure and keep details sharp.

Beyond that I’m not sure how much use my rollers could get in the future with large scale creativity in designing bases for 3D printing. *shrug* Analog creating still has a place with me and some things can still find use. May thos small crumb of insight help anybody reading.

These rollers work great even with air drying clay. So what I have done in the past was make a flat piece of clay, use the rolling pin with the “height adjustment rings” to get even pressure everywhere. After all is dried you can crack it into pieces for basing material. Also works good on XPS foam but you need to apply some more pressure to get a good indentation on the foam. The foam “springs back” a little due to it’s nature of being, well, foam.