Home › Forums › News, Rumours & General Discussion › I made a hot wire so now have a million questions about styrofoam

Tagged: hot wire cutter, styrofoam, Terrain

This topic contains 11 replies, has 4 voices, and was last updated by ![]() blinky465 4 years, 1 month ago.

blinky465 4 years, 1 month ago.

-

AuthorPosts

-

September 30, 2020 at 2:43 pm #1570514

I made a hot wire cutter. I know I’m probably late to the party, but I’m really excited about carving bits of foam for wood and brick effects. At least, I was. But now I’ve hit a problem.

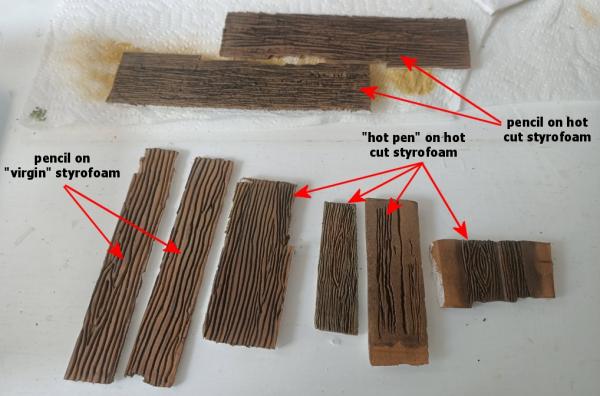

My first bit of carving looked really nice – I just took a sharp pencil, drew a few lines and painted the styrofoam brown (a splash of quickshade and a light drybrush to finish the effect). The result was a really nice, clean, sharp set of lines.

But I’ve noticed that in later pieces, the pencil seems to “snag” or catch on the styrofoam, creating a more “knackered old wood” effect when painted up. I don’t dislike the effect, but what I really loved was the nice, sharp lines on the first piece I made.

It’s not the pencil, it’s definitely the styrofoam. And I narrowed it down to the difference between cut and “virgin” surface (I tried drawing the same wood effect on a fresh piece of styrofoam and the nice sharp details were there again).

So the question is – how do I prepare the cut faces of styrofoam so that it behaves like “virgin” material, ready to take pencil lines? I’ve tried lightly sanding it with emery paper but it didn’t really make much difference. I’ve tried cutting at different temperatures since I put a power control on the cutter (https://www.beastsofwar.com/project/1570235/?order=asc) and hotter temperatures do seem to lessen the effect – but it’s still a problem.

How do you hot wire gurus draw on your cut styrofoam and avoid snagging?

September 30, 2020 at 3:39 pm #1570526

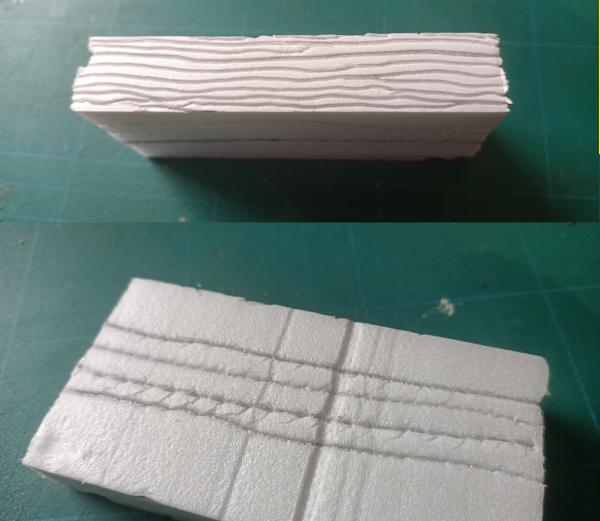

Top – drawing wood grain onto an edge that has not been cut

Bottom – using exactly the same pencil and drawing technique, on the cut surface, the pencil catches and creates lots of tiny tears.

So…. how to make the cut surface more like the uncut edges so they can be drawn on to create textures?

September 30, 2020 at 6:05 pm #1570538I think the ‘virgin’ surface gets compressed and heated during the manufacturing process and has a ‘face hardened’ layer that takes impressions better than a cut surface, could be wrong, but that’s my theory.

I found making a shallow cut with a blade and then defining the line with a blunt pencil helped to reduce tearing

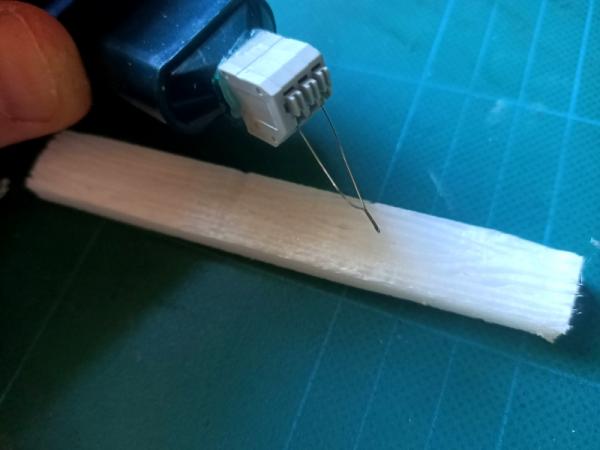

October 1, 2020 at 4:06 pm #1570809Hmmm. That sounds like more hassle than… making a “hot pen” 😉

It’s not so easy to draw straight lines with. But is brilliant for wobbly woodgrain!

October 1, 2020 at 9:08 pm #1570862October 2, 2020 at 11:20 am #1570902

October 1, 2020 at 9:08 pm #1570862October 2, 2020 at 11:20 am #1570902How do you hot wire gurus draw on your cut styrofoam and avoid snagging?

I don’t draw on the cut. Most pieces I do are only substructures. Also XPS comes in various degrees of “sturdiness” and thus reacts different. But I like your pen. Could be that I make my own for some reason…. making holes and stuff.

October 3, 2020 at 8:30 pm #1571401It’s a great little pen! I can change the nib and use different AWG gauge wire for different stroke widths – the variable power means I can get some really tight, narrow lines, or crank it up for nice deep wide ones. For drawing simple circles and cutting holes, it’s brilliant.

My only issue with it is drawing straight lines (for brickwork etc). I can feel an entire CNC project coming on…….

October 3, 2020 at 8:39 pm #1571402I can feel an entire CNC project coming on……

With lights, sounds and hookers… no wait… what?

October 3, 2020 at 9:03 pm #1571405October 4, 2020 at 2:58 pm #1571562Well done @blinky465! To answer your question, not every foam was created equal. You may want to watch this video, which explains differences between foams in more detail and the pencil technique

The Dutch dude recently kickstarted cool book on the topic, it is still possible to order it together with some stencils.

October 4, 2020 at 3:44 pm #1571566The Dutch dude recently kickstarted cool book on the topic, it is still possible to order it together with some stencils.

His Name is Gerard Boom (he has a shop for his hot wire cutter tools https://www.shiftinglands.com/ )and he joined with Michael Martin of the YouTube Channel Tabletop Workshop on this KS project 😉 (Michael is doing all the update videos and pictures) The late pledge is closed but you can pre-order from their coop-partner shop Miniaturicum.

https://www.miniaturicum.de/Tabletop-terrain-from-XPS-foam-Buildings-english

I can’t wait for my copy to arrive 8)

October 4, 2020 at 7:46 pm #1571663 -

AuthorPosts

You must be logged in to reply to this topic.