Reaver Titan Build

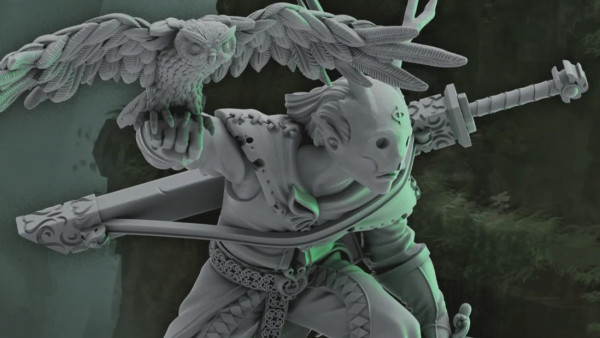

Cataloging, Cleaning, Filling, Filing, dry fitting and creation of a damaged leg plate

Checking everything and making sure its all in good nick, present and then a wash and scub in some detergent to get rid of the mould release that can bugger up a good paint job.

Recreated a leg plate so I can have a diorama later on showing the titan in refit

Used polymorph (heat reactive plastic to make the mould and milliput for the actual part. I then damaged the plate and inserted “granny grating” into the holes then hit the grating with a creme brule torch to melt it a bit.

Having far too much stringing out the build.

Did you have any trouble with the polymorph heat reactive plastic when it was time to release the new part from inside the inner and outer mould?

I have some of this material but have yet to attempt a two part mould.

With polymorph I had the following issues:

Back of plate has rough texture due to polymorph not being hot enough – on the back don’t care.

Curved plate was tough to separate – should have made the mould thinner on the out side

Spray with mould release (wax, soap or vaseline etc)

Final cast was a bit rough as milliput was a bit too firm for such a large cast but fine because i was damaging it.

But it was quite easy – if I wanted a perfect copy I would have used more traditional methods.

nothing to see here