Tiny micro desktop smoke machine

Reverse polarity protection

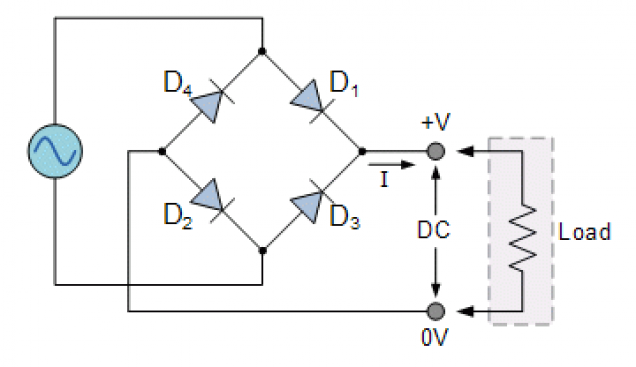

A diode is a clever little device that only allows electrical current to flow one way through it. A bunch of diodes, connected in a certain way, can be used to create a “rectifier” – these are usually used to turn AC or mains electricity into DC (single direction) current. But they can also be used to “flip” an existing DC current, to ensure that we always know which point is positive and which point is negative (or ground) in a DC input.

By using a rectifier, it wouldn’t matter which way around the power and ground wires were connected – it would take any potentially inverted input current and “flip it” to make sure it’s always the right way around.

So before anything on the circuit, I had to introduce a high-current rectifier (since we already know that the coil pulls between 1A – 1.5 Amps, the rectifier needed to be rated to at least 2 Amps).

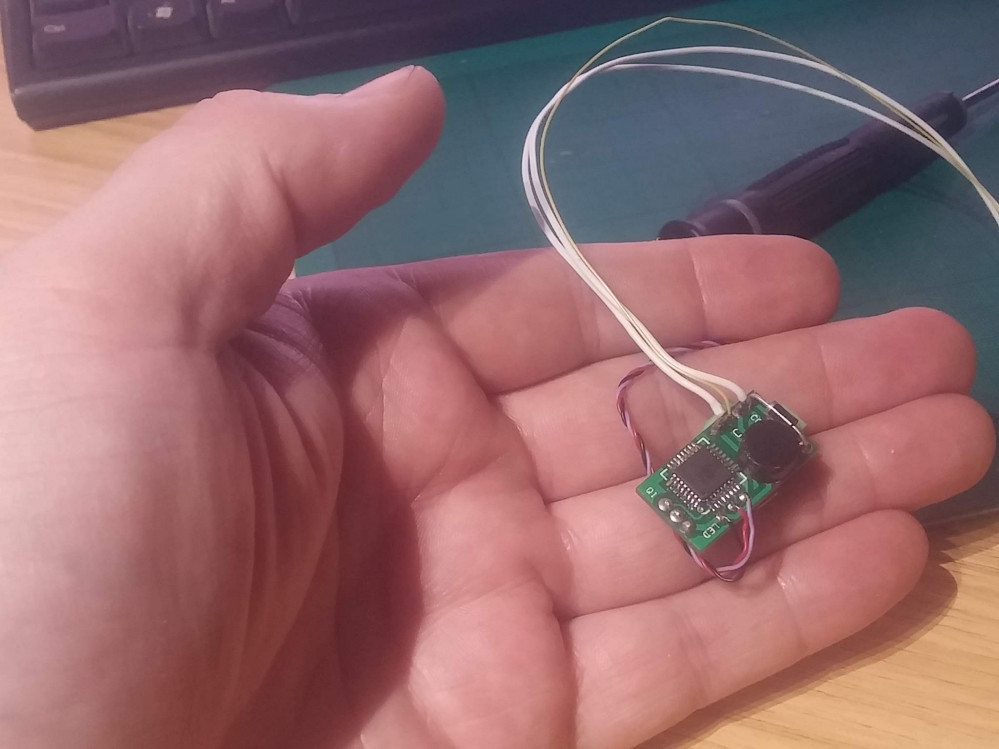

After a few weeks (sadly, work still takes priority so this was very much an evening/weekends project) I had a design that seemed stable and resiliant.

I ordered some PCBs from PCBWay, handed over some cash, waited the necessary 10 days or so, then soldered up a couple of prototypes.

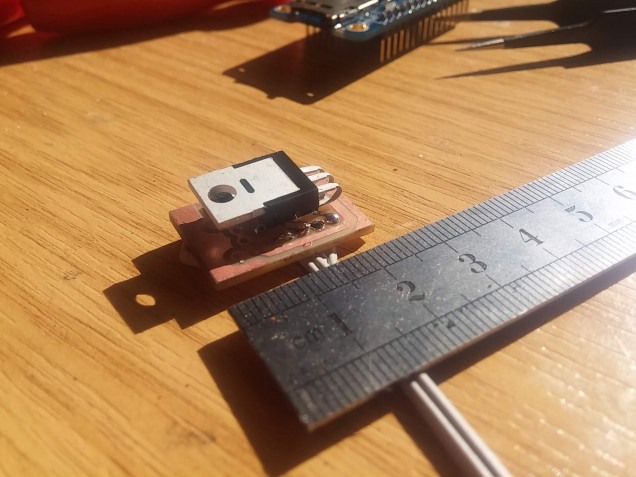

The circuit boards were just 30mm high, but rather “chunkier” (wider) that I would have liked. I’m not sure why. There was just something about them that felt like they were bigger than I would have liked.

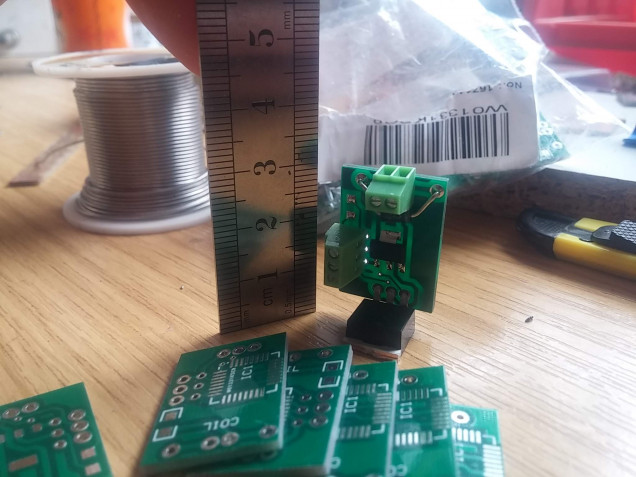

Almost entirely by accident, when soldering a MOSFET to a homebrew circuit board, I stumbled upon a way of “squashing things up” a bit – simply fold the component up over itself!

After another few weekends of trial-and-error, I had another circuit design ready to send off to the factory for production. All I had to do was wait for it – along with a load of rectifier components I’d ordered online – to arrive, and get soldering!

Leave a Reply