Tiny micro desktop smoke machine

Vape smoking juice

At it’s core, a vape cigarette is little more than a battery and a coil – the coil acts as a heater and it has a “wick” through the centre of it. The wick soaks up a mixture of vegetable glycerin and/or propylene glycol and when it hits the heated coil, it immediately vapourises, creating those recognisable plumes of smoke that seem to accompany hipsters that hang around the doorways of trendy cafes.

I figured that since the technology already existed, it’d be the perfect place to start. Except, of course, simply gutting a vape machine wasn’t going to cut it – in terms of 28mm scale, they’re massive.

So the trick was to re-create a controllable heater coil, as small as possible.

It took quite a bit of trial and error to work out the voltage and current requirements to get the coil hot enough to vapourise the PV liquid, without causing “thermal runaway” and making the thing a fire hazard on the tabletop!

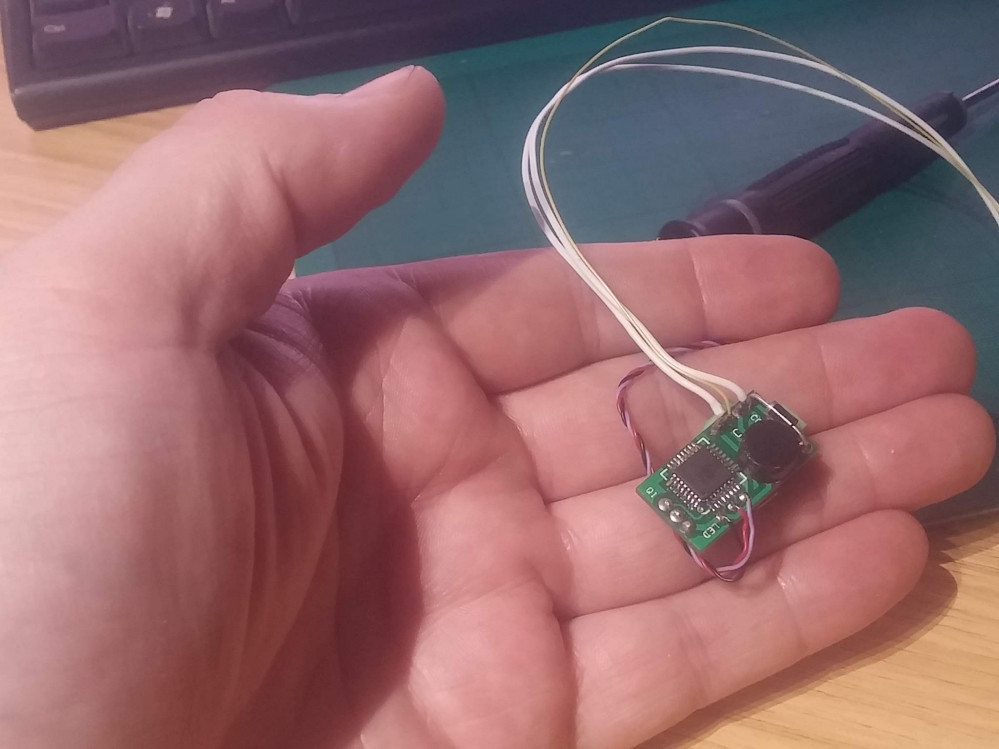

That said, a microcontroller, a high-current MOSFET and some 32AWG wire were pretty much enough to get started. It took a few iterations to realise that, at first, I wasn’t using enough voltage.

Because the microcontroller was running at 5V, I simply used a 5V supply but this wasn’t really enough to get the coil hot enough (and in order to get the coil hot, the resistance had to be so low that the device was pulling 3-4 Amps – that’s a lot for such tiny electronics!)

So I tried using a 12V power supply, and a 5V regulator to step the voltage down; this allowed me to run the microcontroller at 5V but still switch the coil on and off at 12V.

To get the coil hot enough to vapourise liquid, I had to pull about 1 Amp from the power supply; still quite a lot (relatively speaking) but well under the 2A rating of my power supply adapter.

By using a high-speed microcontroller to turn the coil on and off, really quickly, I could simulate a range of power levels – allowing the coil to run between a range of different temperatures.

Unfortunately, this extra complexity would require a little more thought….

Tbh, you can use any vape juice straight off the shelf. I just find that the glycerin on its own isn’t quite so noxious – some of those vape juices are really very sickly; having “bakewell tart” pluming out onto the tabletop every few seconds could get very sickly, really quickly!

Great use of “social media” to throw in a link to your website too 😉