Masters of the Universe

Printing with PLA is easier than ABS

It turns out that printing with PLA is about a hundred times easier than printing with ABS (and to date, fingers crossed, I’ve managed a couple of things and still no nozzle blocking, like I was getting with ABS).

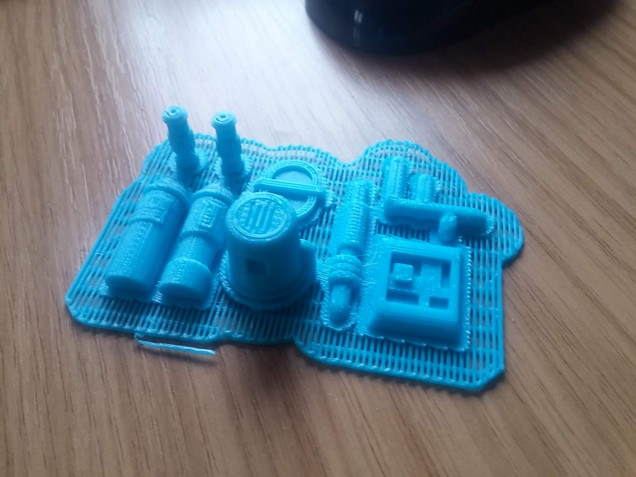

So after printing a few sci-fi greebles successfully, I figured it was time to try Castle Grayskull….

I loaded up the Grayskull stl files (from Thingiverse – https://www.thingiverse.com/thing:2840544) hit print and waited excitedly….

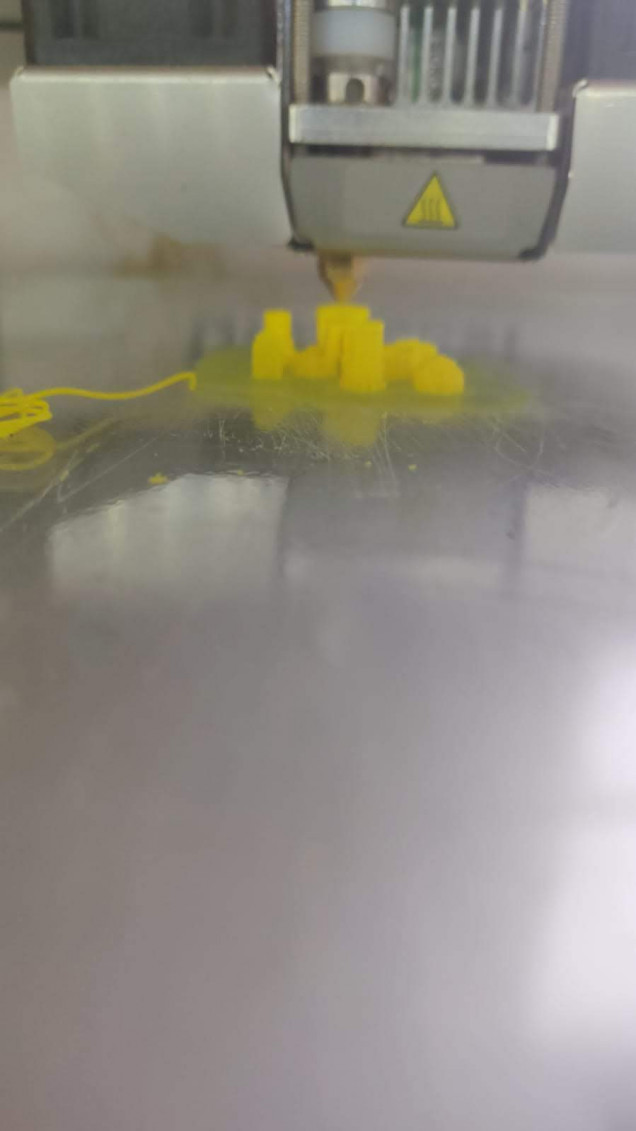

When I returned to the printer, I was disappointed to see that it had gone all “Spinal Tap Stonehenge” on me and instead of printing the door at 55mm high (I just eyeballed it and thought this would be a good size to work from) it tried to print it 5.5mm high!

More problems ensued (the heated bed stopped heating after 15 mins, so the large raft came loose and the entire model warped) so I emailed the files over to Jon at the Eagle Lab in Brighton (if you’re ever anywhere near Brighton, pop it – it’s an amazing version of a pro-end makerspace).

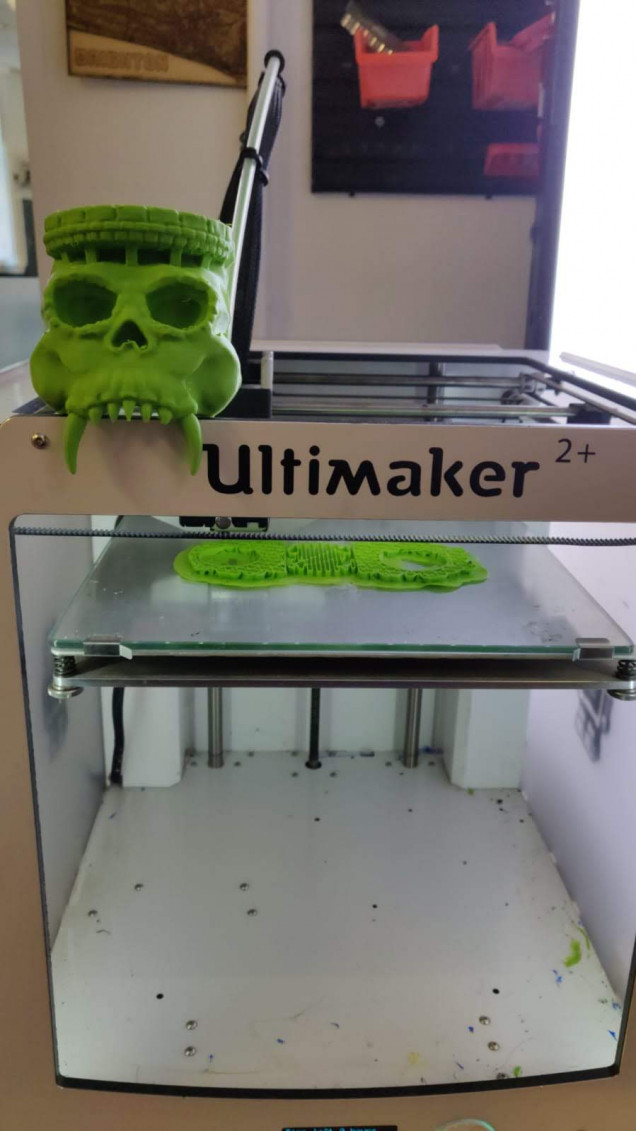

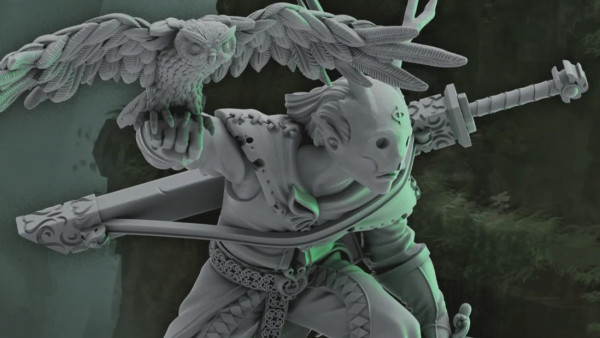

Jon’s Ultimaker 2+ churned out flawless model after model with little or no intervention; just slice the stl, load the gcode, hit print and wait. Each piece had a massive 8-10 hour print time so it took a few days in total to produce these pieces:

After a couple of days, I had a reasonably sized Castle Gray/Greenskull.

Sure, there are plenty more parts needed to make it a complete castle; I figured that the turrets could be made from 32mm and 40mm pipe (the print time on each turret is 12+ hours) and textured with polyfilla.

The entire model needs coating in filler and then sanding back, to help reduce the few areas where banding is obvious (around the eyes and nose and on a few of the vertical sections).

But all in all, I’m quite pleased with the result.

Impressed enough to think that maybe there is something in this 3d printed terrain lark after all…..

Leave a Reply