3D Printing For Wargaming Part One: An Overview!

March 23, 2015 by crew

Why Is It Something You Should Care About?

To be perfectly honest, 3D printing is an overrated technology for home use. Do you need a handle for your plastic shopping bags? Not really. Should you print some new knobs for your kitchen cabinets? They won’t be as good as you think. You’d have to have a really convincing reason to print an iPhone cradle when you can buy them from the pound store in a lot less time and with a lot less effort. Don’t get me wrong, it can be cute to make your own Super-Mario-style cookie cutters.

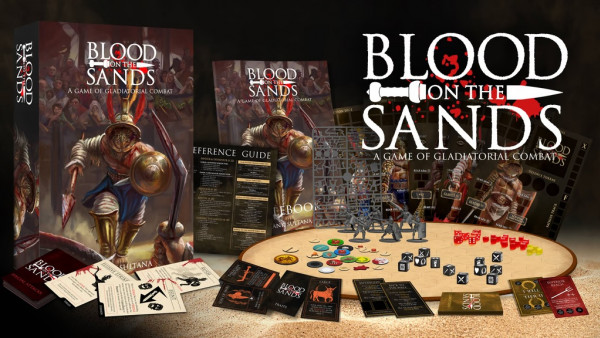

But scale models? Oh-ho-ho, now you’re talking. And what industry is more in need of tabletops full of models than miniature wargaming? OK, maybe model railways, but that’s not my hobby.

3D Modeling

The process starts on a computer in a piece of modeling software. Simply put, a 3D model is a collection of triangles that fit together to make a shape. Often these triangles come in twos to make rectangles. With enough of them, you can sculpt any complex object you like.

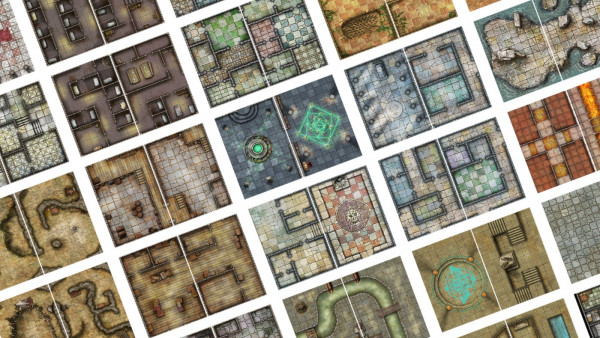

It’s up to the modeller to decide how much detail they want to put in to it. A building could be represented by a simple cube, or it could be made up 50,000 triangles so that details like cracks in walls and rust on gutters are represented. It’s all about how much time you want to take in it’s construction.

Most 3D models are available to download so, if you don’t have an inclination toward modeling, never fear; there are extensive libraries to draw from.

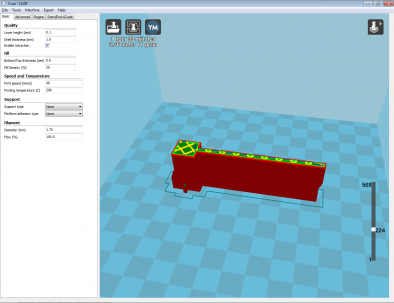

Slicers

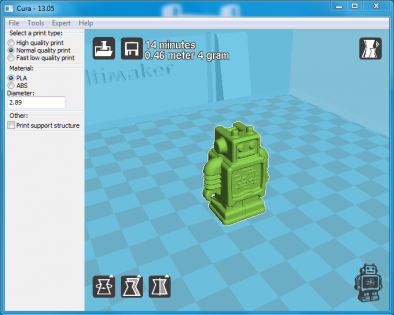

The transformation from 3D model to real-world starts when you load a model into a piece of software called a slicer. The slicing program decides what's supposed to be the inside and what is the outside of your model and then shaves layers from the bottom to the top.

Picture the model lying in a deli slicer and wafer-thin cross-sections fall away on the other side. From this, it makes a list of commands to send to the machine for each slice of your model. You can control things like how much structure will be drawn inside of the model or how thick the outside walls of the piece will be.

In this way, "Printing" is a bit of a misnomer. This is actually more like plotting. The commands tell the machine to trace a shape in X and Y, give a slight nudge to the Z, then start tracing the next slice.

Methods of 3D Printing

There are multiple ways to make these slices appear in the real world. Here are three of the most popular methods that apply to us in the hobby at the moment:

FDM or Fused Deposition Modeling - A hot nozzle with a very fine tip is mounted on the end of a system of motor-driven arms or rails that trace the paths from the slicer. A continuous feed of plastic is fed into the nozzle and melted onto the print bed from above where it cools and “fuses” with the rest of the model. This method is good for architectural pieces and larger organic shapes, but not for small organic shapes like figurines.

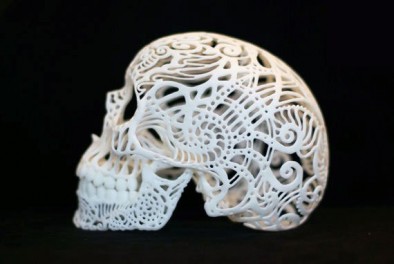

Stereolithography - The low end (consumer) devices in this range have an inverted print bed that sits in a bath of liquid resin. The resin is hardened by UV light, and the container is clear, so that a blue-ray laser can trace the slices on the underside. After every slice, the print bed moves up. Because we’re talking about lasers, the detail level is very fine and we can use this system for things like figurines.

3D Inkjet Printing (with a binding powder) - This style hasn’t become popular for consumers use yet, but it may do in the future. It’s the style of printing best known for when you send away for prints to be made at a 3D printing company like Shapeways. A thin layer of a powder is spread over a flat surface and an inkjet printhead moves over it, spraying it with a binding agent, and sometimes even a colouring additive. Once a layer is done, a new layer of the powder is spread over top and the process repeats until the print is done. This is one of the only methods where any colour texture you produce with your model can be applied to the model as it is being built.

Choosing a Printer

My personal goal for 3D printing was the desire to fill a gaming table full of terrain. For that reason, I chose FDM printing, which is the more popular style for home use. The price for an FDM printer was within what I called ‘reasonable’. I studied videos about how to use them and what the output was like.

Why did I not choose Stereolithography? It is the highest quality consumer device, after all. Well, from what I understood, these are the reasons it didn’t suit me:

- It took longer to print objects

- It was more prone to failure (midway through a print)

- The printing material was more expensive

- You have to keep the device spotlessly clean

While these are the reasons that helped me make my choice, it is entirely possible that you may have different goals or you are not as concerned with the things that I considered barriers. In which case, do some more research and follow what you think is right.

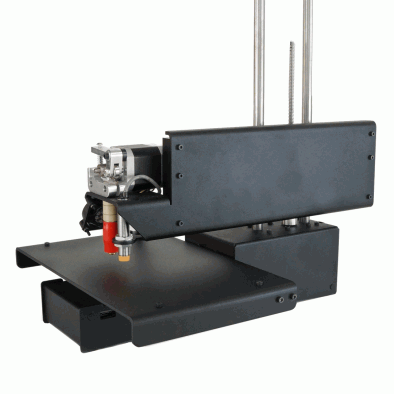

Then it’s a choice in manufacturer. As with most things you purchase, it comes down to cost versus quality and so this is where reviews are very important to read. I chose the PrintrBot Simple Metal as (at the time) it was reviewing well as a machine that rivaled the quality of printers that cost three times as much.

Another choice that I had to make when I bought my machine was to pay slightly more for a pre-built machine or to construct it myself. It was a hard choice, but I decided to build it myself as I thought that they would only sell kits if it was relatively easy to do. In terms of skill level, it has been compared to building an RC car. Even so, I studied hard, watching numerous build videos that had been made for my specific printer. It was nerve-wracking! I had one issue that I thought would require a new part, but it turned out I had just wired something incorrectly. The build took two hours in total, with three additional hours of problem solving and depression. Followed by extreme happiness!

My printer, the Printrbot Simple Metal, before and after construction:

Next Time

The next article in this series will be about the issues and considerations you should think about before diving into the world of 3D Printing.

Popular FDM Printers:

www.printrbot.com

www.makerbot.com

www.ultimaker.com

Popular Stereolithography Printers:

www.formlabs.com

www.peachyprinter.com

Mail Order Prints (3D inkjet printing):

www.shapeways.com

Would you like to know more?

If you would like to write articles for Beasts of War then please contact us at [email protected] for more information!

"In this way, "Printing" is a bit of a misnomer. This is actually more like plotting..."

Supported by (Turn Off)

Supported by (Turn Off)

"I chose the PrintrBot Simple Metal as (at the time) it was reviewing well as a machine that rivaled the quality of printers that cost three times as much..."

Supported by (Turn Off)

It’s 2015 already, where’s my 3D printed hoverboard?

Also, great article. Very informative 🙂

And where are the other 15 jaws movies? YOU LIED TO ME SPIELBURG!

Very nice article

Great article Tobyn and very interesting. I’ve been hovering on the edges for a while now of joining up the gap between my 3D modelling and resin casting mainly as a way of prototyping the primitives for me to then add the finished detail for casting. I’m also looking at it as a way of evaluating some of my designs prior to committing them to a bureau printer for a higher quality master and of course just to use as a learning platform. Went with an M3D Micro as a seriously cheap low cost FDM entry, just waiting for it… Read more »

Thank you! That printer looks good; small price and high quality. BoW tells me my next article will be out next week.

Very very nice article. I’m a 3D modeller myself (for videogames, but close enough) and I’m very interested in trying the 3D printing.

Will look after the next articles for more info ^_^

I make video games too. For 18 years now! It’s a real trip to see my 3D models actually sitting in my hands.

FYI, here’s where I am at with my 3D models:

http://imgur.com/RMD6vcR.jpg

Finally something to cut through the be and explains where we are ATM. Nice job Tobyn!

*bs (bloody autocorrect)

Well as I implied and said outright for a while now I am a self confessed Ludite. I however followed this article and it was clear and precise, in short really well done and pitched at a level that was really informative. I draw and paint and scratch build what I can not purchase or alter to my own ends. Guys I mean it this article has me clearly wondering wether I should start to learn how to draw in these 3d formats on the old Mac. I thank you for demystifying what I would have thought was well beyond… Read more »

That’s great! I know there are people out there who skimmed it and said “How basic” but if they already knew then the article wasn’t for them. I get into more detail later.

nice article 😉 looking forward to seeing the future parts 🙂 I work a lot with 3d printing myself for miniatures sculpting 🙂 and it’s been fascinating seeing how the tech has improved just over the last few years 🙂 … I still feel wax printers are the best, but sometimes people forget to not hold the prints in their hands for to long 😛 ha ha ha for home printing, I’ve been getting very excited lately about the results you can get with the Form 1 printer you talked about in the article 🙂 I’d love to get one,… Read more »

Thanks! The next article talks about the limitations and problems that you may run into or have to consider before you get into it. It’s by no means a perfect system, but I find that if you work with the problems then you can still be satisfied.

yeah, I think it’s like that with many things, just need to work within the limitations 🙂

and of course, you can always count on a bit of 1000 grit “wet and dry” sandpaper to come to the rescue 😉 😛 ha ha

looking forward to reading the next article 😉

Oh, and I try to avoid the discussion about printing figurines because I haven’t had any experience with it. That’s definitely the elephant in the room for the industry, but Warren was eloquent about it in one of the weekenders.

i’ve been looking @ 3d printing for models, and the Form 1 (pictured with that orangy case thing) which uses the liquid resin seems to be the only consumer (ie. under $5000) 3d printer that can get the proper detail level. It appears there may still be a slight texture but that can probably be sanded off.

Issues though; the liquid resin it uses is very expensive. If you wanted to make a large model, it’s probably cheaper to commission a professional artist to just sculpt the damn thing for ya/

yeah, the Form 1 is a bit too expensive for my wallet right now (¡ ~ ¡) luckily I know some printing companies I can get good prices with 😉 … but at the same time, how many prints would you get for the price of a Form 1 ? after a certain amount of time it would pay for itself … but still, the price tag is huge (¡ ~ ¡) …. but then, only 3 years ago the only home 3d printer with a quality level close to it cost …. $30,000 (X , X) …. yeeeeaaahhhh (O… Read more »

Great article I would like to know more!

🙂 “Would you like to know more?” was supposed to be placed just before all the links.

A great and very objective article. I see 3D printers as accidentally hatching a tyranasourus egg. It is cute now but in a few years it will eat you and go on the rampage. So in the long term I fear them as they could destroy a vast number of miniature manufactures. In another 5 years our home computers will be more than 3 times as powerful as the home computer just being released now and they will cost half as much. In 5 years time the cost of a 3D will be what we pay for a high end… Read more »

This is all a possible outcome for the industry. But Warren has made a valid point that this happened with the music industry. Making and ripping mp3s from CDs was incredibly easy, and people thought that it was going to be impossible to make money producing music. But iTunes made a system which made music cheap and easy to access while making devices that were desirable to own. MP3s are still easy to acquire for free, but they’re even easier to get for a small amount of money. But who knows?

… these are the reasons no miniature company will ever do on demand home 3d printing 😛

… and the 3d scanning part is something I never thought about before,

… that could be the BIG problem, very good points there

Nice intro article – looking forward to more! You might want to check out our 3D Printing for Games Google + Group for lots of help and many kindrid spirits!

https://plus.google.com/u/0/communities/106272753855894429725